-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

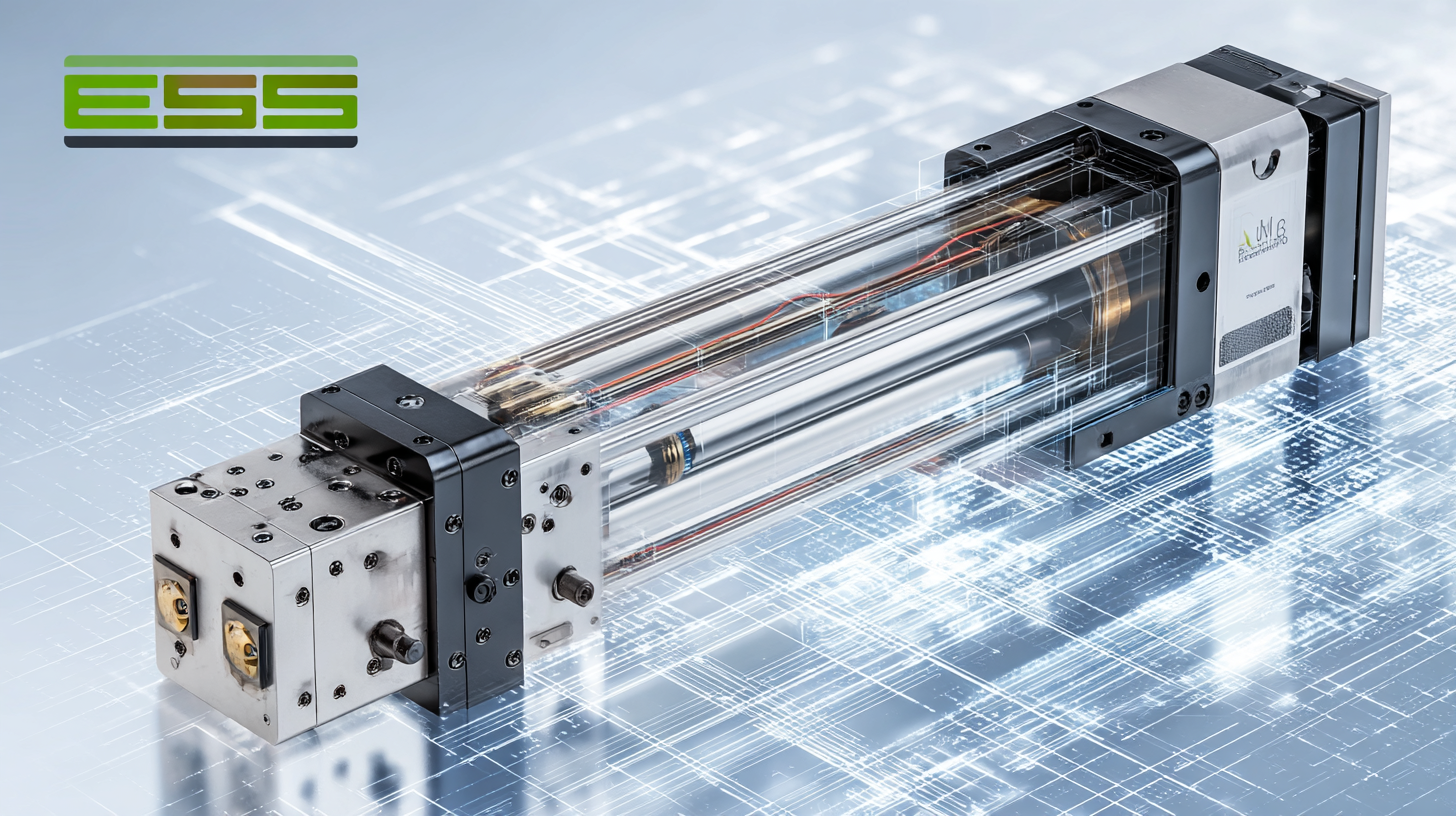

As we venture into the future of manufacturing, the importance of Linear Servo Motors continues to rise, significantly impacting production efficiency and cost-effectiveness. According to a recent report by MarketsandMarkets, the linear motion system market, which includes Linear Servo Motors, is projected to reach USD 10.27 billion by 2025, growing at a CAGR of 8.2%. This growth is driven by the increasing demand for precision and speed in automated processes across various industries, including automotive and electronics. Furthermore, the integration of advanced functionalities such as real-time monitoring and predictive maintenance is enhancing the after-sales service advantages and reducing overall maintenance costs. As manufacturers adapt to these innovations, understanding the implications of Linear Servo Motors on operational strategies will be essential for maintaining a competitive edge in the global marketplace.

The rapid evolution of technology is setting the stage for significant advancements in linear servo motors, which are already making waves in various manufacturing sectors. Key emerging technologies such as artificial intelligence, advanced materials, and automation systems are playing pivotal roles in driving these developments. AI can optimize motion control algorithms, enhancing the precision and efficiency of linear servo motors, which is crucial for applications requiring high-speed and accurate positioning.

Additionally, the introduction of smart materials, like shape-memory alloys, is revolutionizing the design and functionality of linear servo motors. These materials allow for lighter, more responsive systems that can adapt to changing operational demands. As manufacturers increasingly adopt automated systems, the synergy between linear servo motors and robotics will further streamline production processes, leading to higher productivity and lower operational costs. By 2025, these innovations will not only enhance the capabilities of linear servo motors but also redefine the landscape of global manufacturing.

| Innovation Area | Expected Advancements | Potential Industry Applications | Expected Impact on Manufacturing |

|---|---|---|---|

| High-Efficiency Motors | Reduction in energy consumption by 20% | Automotive, Robotics | Lower operating costs |

| Smart Motor Control | Integration of AI for predictive maintenance | Manufacturing, Aerospace | Improved uptime and reliability |

| Miniaturization | Development of compact designs | Consumer Electronics, Medical Devices | Increased design flexibility |

| Enhanced Feedback Systems | Real-time performance monitoring | Industrial Automation | Higher precision in operations |

| Eco-Friendly Materials | Use of sustainable components | Energy Management, Green Technology | Reduced environmental impact |

The integration of linear servo motors in global manufacturing is poised to transform efficiency and precision, yet several key challenges must be addressed. According to a recent report by MarketsandMarkets, the linear motion market is projected to reach $16.5 billion by 2025, driven largely by advances in automation. However, manufacturers face hurdles such as compatibility with existing systems, high initial investment costs, and the need for skilled labor to manage complex technologies. These challenges can hinder the seamless adoption of linear servo motors, impacting overall production timelines.

To help overcome these obstacles, manufacturers should focus on phased implementation strategies. Gradual integration of linear servo motors into existing workflows allows teams to adapt gradually, minimizing disruptions. Moreover, investing in employee training programs equips staff with essential skills, ensuring they are prepared to handle new technologies effectively.

Another significant challenge is data management, as linear servo motors generate vast amounts of operational data that can overwhelm traditional systems. Implementing advanced data analytics solutions can streamline processing, enabling manufacturers to harness insights that enhance performance. By addressing these key challenges, industries can unlock the full potential of linear servo motors, driving innovation in manufacturing practices by 2025.

As we look towards 2025, the integration of AI and robotics is poised to transform the performance of linear servo motors significantly. A recent report by the International Federation of Robotics highlights that by 2025, the global industrial robot market is expected to grow to $80 billion, with linear servo motors playing a critical role in this evolution. These motors are renowned for their precision and speed, making them essential in various manufacturing applications. By incorporating AI-driven algorithms, manufacturers can enhance motion control, leading to improved operational efficiency and reduced downtime.

**Tip:** To maximize the benefits of incorporating AI in your linear servo systems, focus on predictive maintenance techniques. This approach can reduce unplanned machine failures by up to 30%, according to a study from McKinsey & Company. By leveraging real-time data, manufacturers can anticipate potential issues and address them proactively, ensuring smoother operations.

Moreover, robotics equipped with advanced linear servo motors offer enhanced capabilities in assembly lines, allowing for more flexible and adaptable manufacturing environments. According to a report from MarketsandMarkets, the demand for smart factory solutions is projected to reach $500 billion by 2025, driven in part by advances in linear actuator technology. This shift emphasizes the need for manufacturers to invest in AI-enhanced linear servo motors, which are critical for meeting the growing demand for customization and efficiency in production processes.

**Tip:** Consider investing in training programs for your workforce to ensure they are well-versed in the latest AI tools and techniques. This can lead to significant performance improvements, with companies reporting efficiency gains of up to 25% after upskilling their employees.

The manufacturing landscape is on the brink of a revolutionary shift as advanced linear servo motors emerge as a key technology driving sustainable solutions by 2025. These innovative motors offer unparalleled precision and efficiency, significantly reducing energy consumption and waste. A recent report by MarketsandMarkets predicts that the global linear motor market will grow from USD 2.2 billion in 2020 to USD 4.8 billion by 2025, highlighting the increasing adoption of these technologies in various manufacturing sectors. The integration of linear servo motors not only enhances production speed but also contributes to lower carbon footprints, aligning with global sustainability goals.

Tips: When considering the implementation of linear servo motors in your manufacturing processes, assess the energy savings and waste reduction potential. It's important to conduct a thorough energy audit to determine current usage and identify areas where linear motors can create efficiencies. Furthermore, understanding the lifecycle benefits of these motors can provide a more comprehensive view of their impact on sustainability.

As manufacturers seek to innovate, switching to advanced linear servo motors can yield significant benefits. According to a study by the International Energy Agency, improving motor efficiency can reduce energy costs by up to 20-30%. By focusing on these technologies, companies not only enhance their operational capabilities but also support the larger shift towards sustainable manufacturing practices, ensuring they remain competitive in an evolving market.

The evolution of linear servo motors is set to significantly transform global manufacturing by 2025. As industries increasingly adopt automation, these motors will play a crucial role in enhancing precision and efficiency in production processes. Innovations in design and technology are making linear servo motors more accessible and cost-effective, thus promoting their integration across various sectors. From automotive to electronics, the versatility of these motors is poised to streamline operations and reduce downtime, ultimately boosting productivity.

The evolution of linear servo motors is set to significantly transform global manufacturing by 2025. As industries increasingly adopt automation, these motors will play a crucial role in enhancing precision and efficiency in production processes. Innovations in design and technology are making linear servo motors more accessible and cost-effective, thus promoting their integration across various sectors. From automotive to electronics, the versatility of these motors is poised to streamline operations and reduce downtime, ultimately boosting productivity.

Another notable trend is the growing emphasis on sustainability in manufacturing practices. Linear servo motors offer the advantage of energy efficiency, which aligns with the global push towards reducing carbon footprints. By utilizing advanced materials and intelligent control systems, manufacturers can minimize waste while maintaining high performance. This shift not only reflects a commitment to environmental responsibility but also meets the rising demand for greener solutions amongst consumers and stakeholders. As these trends unfold, the impact of linear servo motors on global manufacturing will be profound, reshaping how products are designed, produced, and delivered.