-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

As we stand on the brink of a technological revolution, the landscape of intelligent motion control is evolving at an unprecedented pace. Central to this evolution is the Servo Motor Drive, a pivotal component that not only enhances operational efficiency but also opens new avenues for automation across various industries. The integration of digital technologies has redefined production standards, enabling manufacturers to achieve higher precision and responsiveness in their machinery. This blog will explore the significance of Servo Motor Drives in shaping the future of motion control, examining the emerging trends and the reasons why these advanced systems are becoming indispensable in today's competitive market. From improved energy efficiency to their role in facilitating Industry 4.0, the advantages of adopting sophisticated Servo Motor Drives are vast and far-reaching. Join us as we delve into the transformative potential of this critical technology.

The rise of intelligent motion control systems is a pivotal shift in the landscape of Industry 4.0, where automation and smart technologies converge to enhance operational efficiencies. According to a report by MarketsandMarkets, the global motion control market is expected to reach $25 billion by 2025, signifying a compound annual growth rate (CAGR) of 6.9%. This growth is largely driven by the increasing adoption of servo motor drives, which are crucial for precise control in manufacturing processes.

In this intelligent era, companies are leveraging advanced servo motor drives to optimize production workflows and enhance system reliability. A report by Research and Markets highlights that smart servo systems can significantly reduce energy consumption—up to 30%—by optimizing real-time motor performance. Additionally, the integration of AI and IoT technologies into motion control systems enables predictive maintenance and real-time monitoring, further boosting productivity and minimizing downtime. As industries transition to more automated and intelligent frameworks, the demand for sophisticated motion control solutions will undoubtedly continue to escalate, paving the way for smarter manufacturing practices.

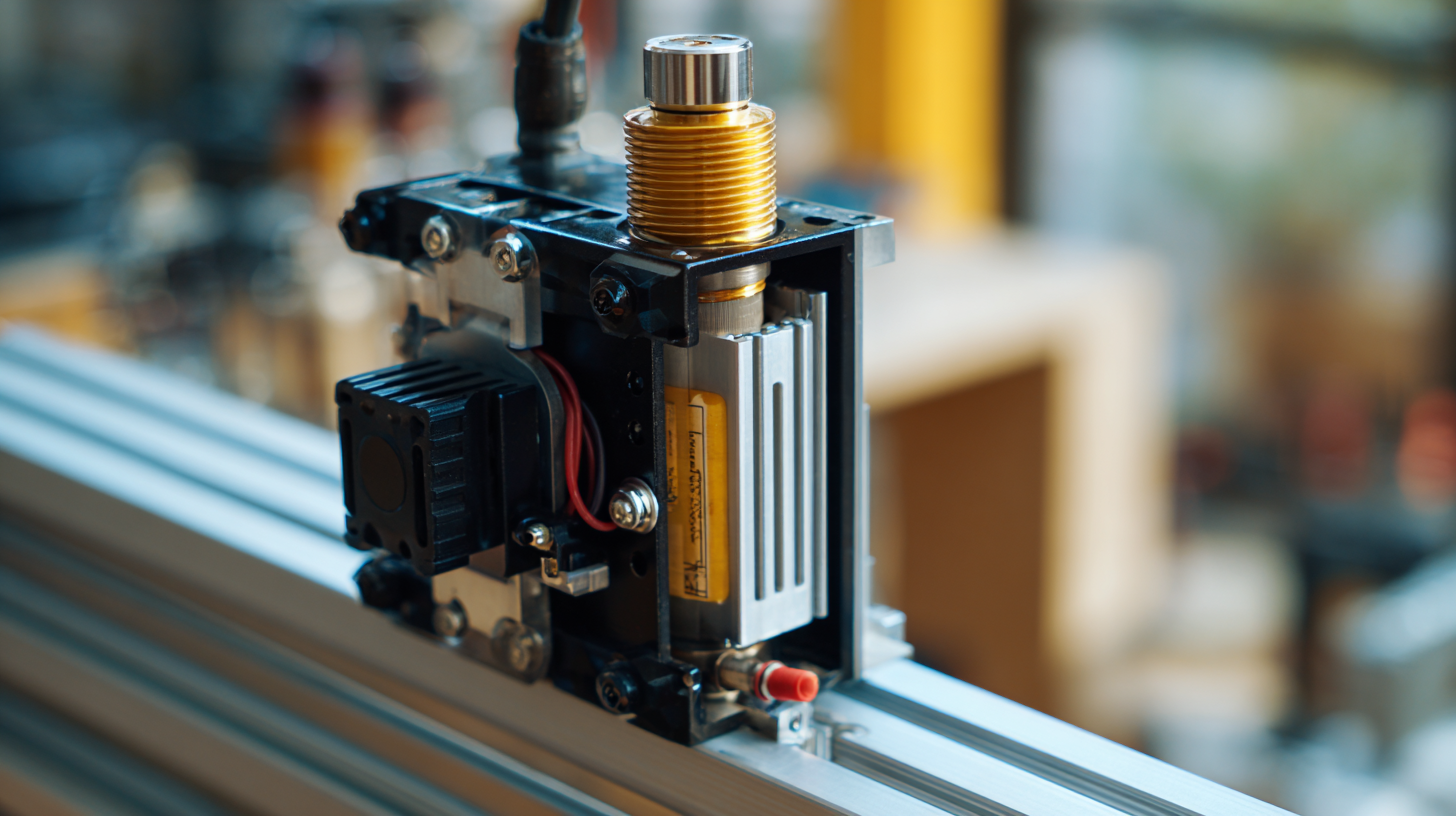

As the servo motor market continues to expand, projected to reach over $13.52 billion by 2024 and grow at a CAGR of 6.9% through 2030, manufacturers and engineers are increasingly focused on the key features that define high-quality servo motor drives. In the realm of intelligent motion control, precision, reliability, and adaptability become paramount. A robust servo motor drive should offer advanced feedback control mechanisms, ensuring real-time adjustments to optimize performance even in dynamic environments.

When selecting a servo motor drive, consider the integration of features like adaptive control algorithms, which enhance precision and responsiveness. Additionally, look for drives with built-in safety protocols and diagnostics to facilitate maintenance and reduce downtime. The ability to interface with modern automation platforms and support for various communication protocols further underscores a drive's in an evolving industrial landscape.

Tips for enhancing motion control effectiveness include investing in drives that feature improved thermal management capabilities and energy efficiency ratings. This not only boosts operational lifespan but also contributes to overall sustainability in manufacturing processes. Prioritizing these attributes will elevate the performance of motion control applications across diverse industries, paving the way for innovation and enhanced productivity.

When evaluating the future of intelligent motion control and selecting the best servo motor drive, one crucial aspect that cannot be overlooked is the manufacturer's reputation. Certifications and industry standards serve as critical indicators of quality and reliability in the highly competitive landscape of motion control technologies. Organizations that adhere to established standards such as ISO 9001 or IEC 61508 demonstrate a commitment to quality management and safety, ensuring that their products meet rigorous performance benchmarks.

Moreover, certifications from industry-specific bodies assure clients that the manufacturer meets the necessary guidelines for technical efficiency and operational safety. Manufacturers with a strong track record of compliance with these standards not only inspire trust but also provide invaluable support and resources, reflecting their dedication to innovation and excellence in servo motor technology. Engaging with manufacturers who prioritize these credentials can significantly enhance the performance capabilities and longevity of intelligent motion systems, paving the way for a future marked by increased automation and precision in industrial applications.

| Manufacturer | Certifications | Industry Standards | Product Range | Customer Rating |

|---|---|---|---|---|

| Manufacturer A | ISO 9001, CE | IEC 61131, ANSI | Servo Motors, Drives, Controllers | 4.5/5 |

| Manufacturer B | UL, RoHS | ISO/TS 16949, UL 508 | AC Motors, Brushless Servos | 4.7/5 |

| Manufacturer C | ISO 14001, CE | ISO 9001, IEC 61508 | Servo Drives, Linear Motors | 4.6/5 |

| Manufacturer D | CE, FCC | ISO 9001, AEMT | High Torque Servos, Control Systems | 4.4/5 |

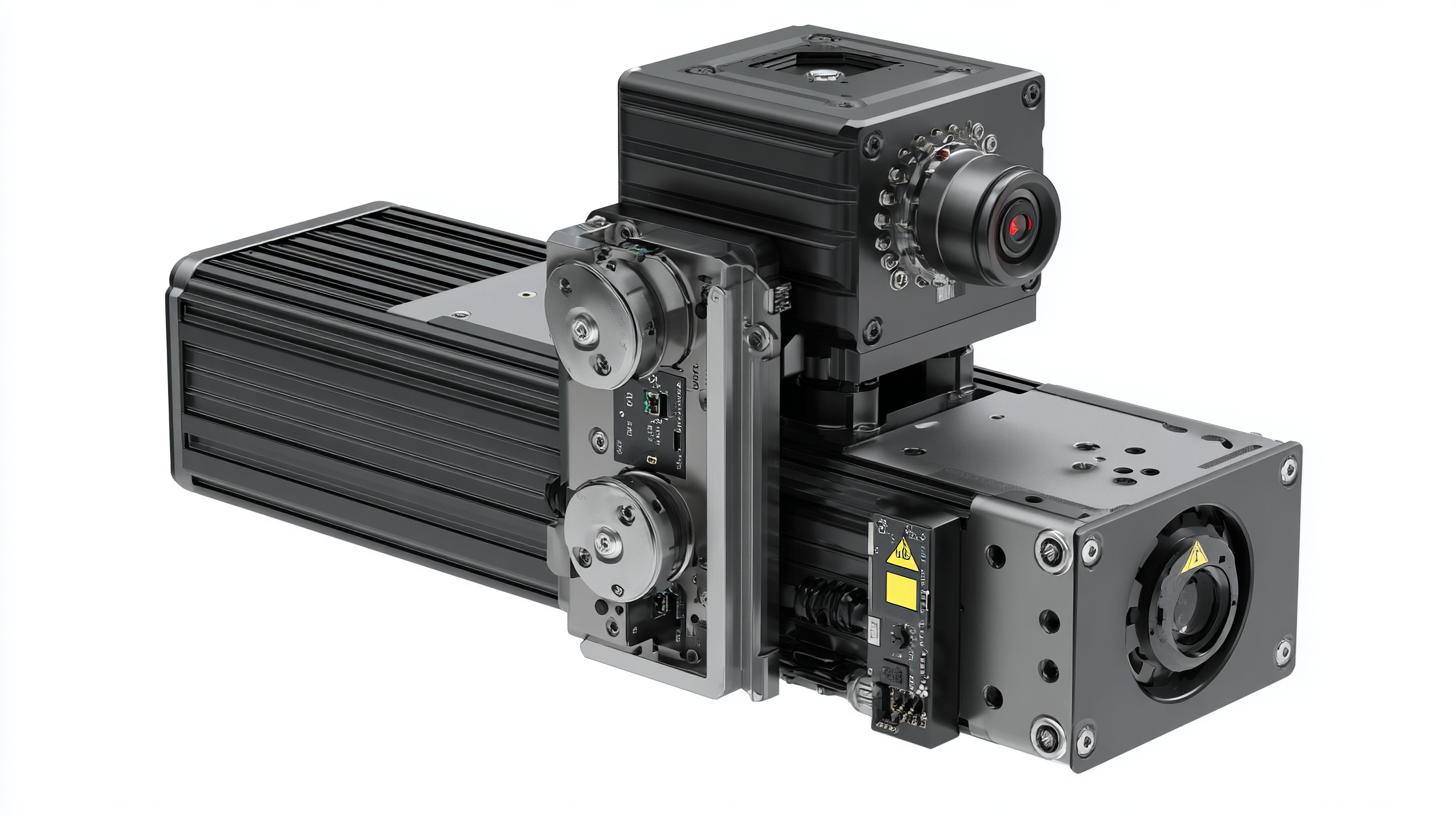

The servo motor drive market is rapidly evolving, with several manufacturers leading the charge in intelligent motion control technology. Companies like Siemens, Yaskawa, and Mitsubishi Electric have introduced advanced servo systems that enhance performance and energy efficiency. Each of these manufacturers employs unique strategies and technologies to cater to diverse industrial applications, making it crucial to analyze their offerings to identify the best fit for specific needs.

Siemens stands out with its Sinamics series, which offers high flexibility and integration capabilities for various automation tasks. Yaskawa, on the other hand, is renowned for its Sigma series, emphasizing precise control and robust performance. Meanwhile, Mitsubishi Electric provides an impressive range of options with its MELSERVO series, focusing on high-speed operation and compact design. By comparing these leading manufacturers, businesses can make informed decisions to optimize their production processes, ultimately pushing the boundaries of what is possible with intelligent motion control.

The field of servo motor technology is rapidly evolving, driven by innovations that promise to transform automation across various industries. One of the most significant trends is the integration of artificial intelligence and machine learning into motion control systems. These advancements allow for real-time data analysis and adaptive learning, enabling servo motors to optimize performance, reduce energy consumption, and enhance precision in complex tasks. As a result, manufacturers can achieve greater efficiency and flexibility in their production processes.

Another exciting development is the push towards miniaturization and increased power density in servo motors. This trend facilitates the creation of smaller, lighter machines that do not compromise on performance. Coupled with advanced materials and manufacturing techniques, these innovations make it possible for servo drives to operate in even more demanding environments. Additionally, enhanced communication protocols and IoT connectivity are paving the way for smarter, more interconnected systems, allowing for predictive maintenance and improved operational oversight. As these technologies continue to advance, they will undoubtedly shape the future landscape of automation, making intelligent motion control an integral part of industry growth.