-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the ever-evolving landscape of automation, the choice of motion control components plays a critical role in the efficiency and precision of operations. Renowned industry expert Dr. John Smith, a leading figure in automation technology, emphasizes the significance of selecting high-quality servo motors. He states,

"The reliability and performance of a system hinge on the type of servo motors utilized, and Mitsubishi Servo Motor stands out as a top contender."

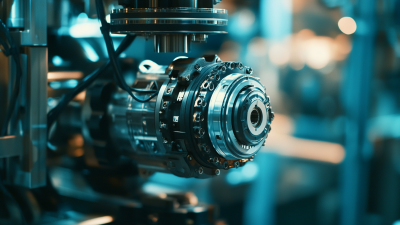

This article delves into the top ten benefits of using Mitsubishi Servo Motor for various automation needs. Known for their robust construction and advanced technology, Mitsubishi Servo Motors offer unmatched performance in precision control, energy efficiency, and adaptability across diverse applications. As industries strive for greater automation, understanding the advantages of these exceptional motors becomes essential.

From manufacturing lines to robotics, Mitsubishi Servo Motors are designed to enhance productivity and operational excellence. By exploring the unique features and capabilities that these motors bring to the table, businesses can unlock new levels of efficiency and effectiveness in their automated processes.

Mitsubishi servo motors are at the forefront of precision control technology, making them an indispensable asset for automation needs. With the global integrated servo motor market valued at $5.29 billion in 2023 and projected to grow significantly, reaching up to $8.75 billion, the demand for high-performance control systems is clearly on the rise. This growth underscores the importance of utilizing servo motors that can offer precise motion control, ensuring high efficiency and accuracy in various applications.

One of the standout features of Mitsubishi servo motors is their ability to provide exceptional power and precision. By integrating advanced technologies, these servo motors enable manufacturers to achieve finer control over their production processes. For instance, a recent market report highlighted in the high-performance linear servo motor sector indicates that innovations in motion control technology are vital for maintaining a competitive edge. Companies looking to modernize their equipment and improve operational efficiency find that implementing Mitsubishi servo solutions not only enhances performance but also optimizes resource utilization, directly impacting overall productivity and profitability.

| Benefit | Description |

|---|---|

| High Precision | Provides exceptional accuracy in positioning and speed control. |

| Reliability | Durable design ensures consistent performance with minimal downtime. |

| Energy Efficiency | Optimized power usage reduces operational costs. |

| Advanced Control Features | Integrated control algorithms improve dynamics and responsiveness. |

| Compact Size | Space-saving design allows for easy integration into various systems. |

| Broad Application Range | Suitable for diverse industries including robotics, CNC machining, and assembly automation. |

| User-Friendly Interfaces | Simplified setup and operation with intuitive programming options. |

| Feedback Mechanisms | Real-time feedback ensures optimal performance and accuracy. |

| Global Support | Extensive support network for installation and maintenance. |

| Cost-Effectiveness | Offers a good balance of performance and price, providing value for money. |

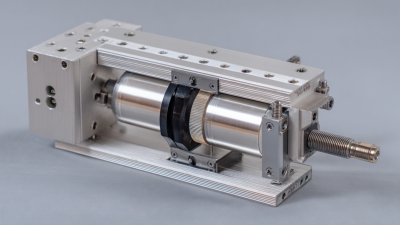

Mitsubishi servo motors have become a cornerstone in modern automation systems, particularly due to their enhanced energy efficiency. These motors are designed to optimize performance while consuming less power, making them ideal for various applications in manufacturing and process automation. By utilizing advanced technologies such as feedback control and precision positioning, Mitsubishi servo motors significantly reduce energy wastage, allowing companies to lower their operational costs while ensuring peak performance.

Moreover, the energy efficiency of Mitsubishi servo motors contributes to a smaller carbon footprint, aligning with the global push for sustainable manufacturing practices. With their ability to operate at lower power levels without sacrificing speed or precision, these motors help businesses meet environmental regulations and goals. The reduced energy consumption not only translates to cost savings but also enhances the overall reliability and longevity of the automation system, making them a smart investment for industries aiming to improve their production capabilities while remaining eco-friendly.

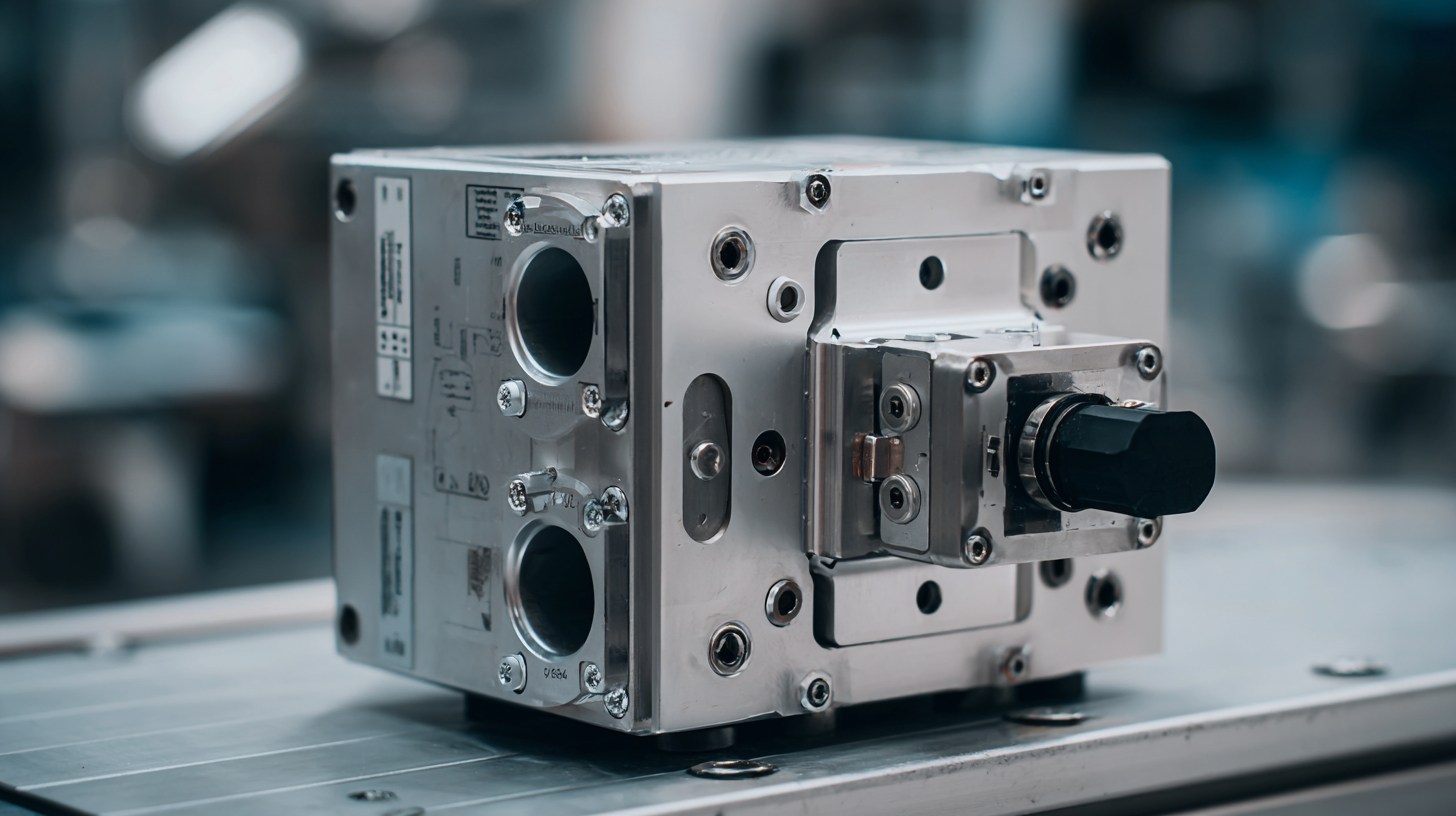

Mitsubishi servo motors are increasingly recognized for their reliability and durability within industrial settings. According to a report published by the Robotics Industry Association, the global industrial robotics sector is expected to grow at a CAGR of 9.5% from 2021 to 2028, highlighting the critical importance of dependable components like servo motors in automation systems. Mitsubishi servo motors excel in minimizing downtime through superior engineering and robust materials, which is essential for maintaining productivity in high-demand environments.

Furthermore, Mitsubishi’s advanced feedback control technology ensures that servo motors operate with remarkable precision, enhancing both performance and longevity. A study from the International Federation of Robotics indicates that automation systems with high reliability can reduce operational costs by up to 20%, emphasizing the need for durable components. By integrating Mitsubishi servo motors, manufacturers can expect a significant reduction in maintenance requirements and associated costs while ensuring consistent performance across various industrial applications, thereby solidifying their position in the competitive market.

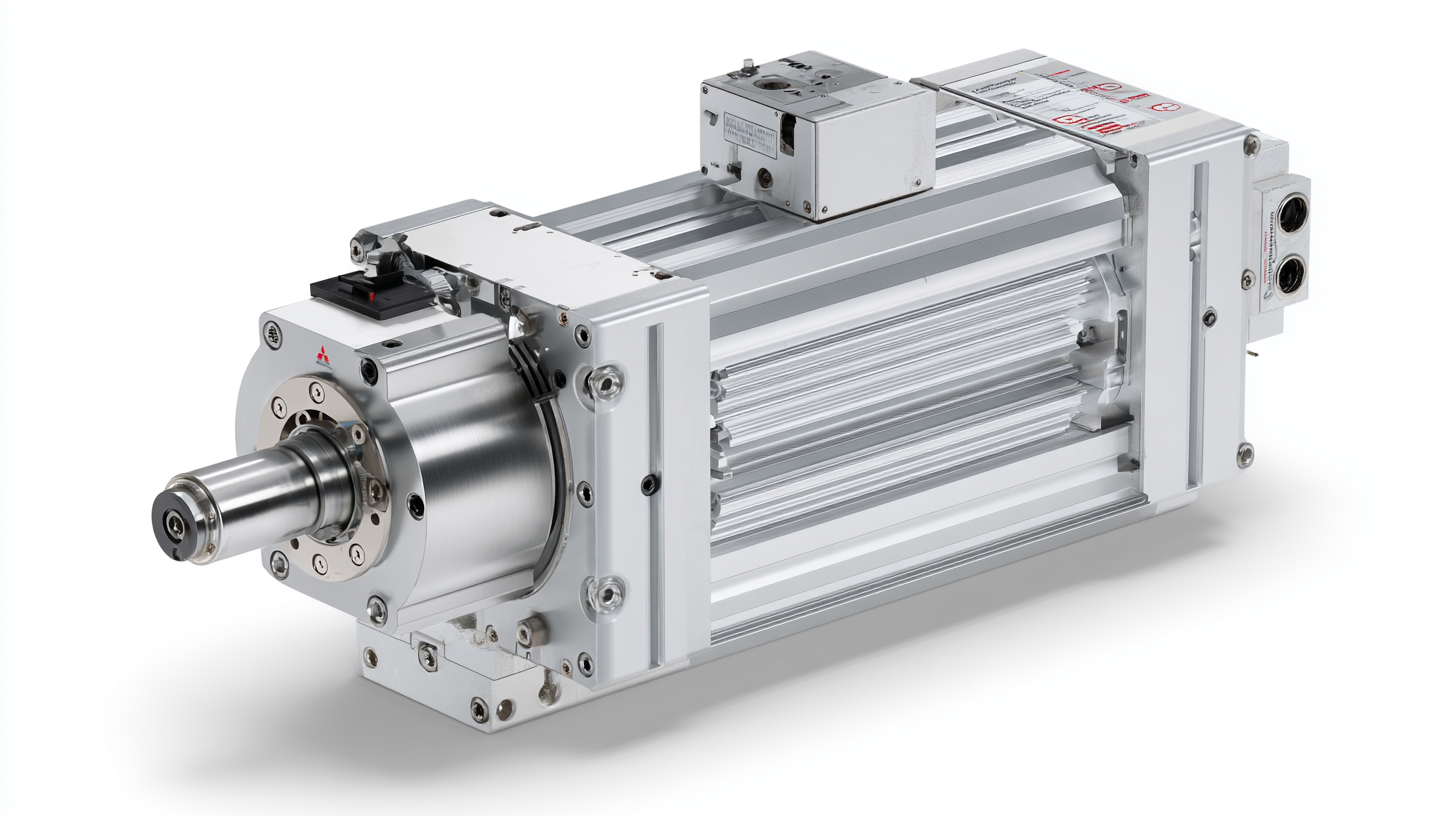

Mitsubishi servo motors stand out in the industry for their versatile integration options, making them an ideal choice for various automation needs. The seamless compatibility with existing systems is a significant benefit that allows organizations to upgrade their automation capabilities without overhauling their entire infrastructure. According to a report by MarketsandMarkets, the global servo motor market is projected to reach $11.5 billion by 2026, indicating a growing recognition of the importance of integration with pre-existing technologies. This flexibility not only reduces downtime during the transition but also leverages current investments in legacy systems, maximizing return on investment.

Furthermore, Mitsubishi servo motors utilize advanced communication protocols such as EtherCAT and CC-Link, facilitating easy integration with a wide range of automation equipment. Research conducted by Technavio predicts that the growing trend of Industry 4.0 will drive a compound annual growth rate (CAGR) of 6% in the servo motor market from 2021 to 2025. This trend underscores the need for systems that can effectively communicate and coordinate between newer smart technologies and established mechanical components. By choosing Mitsubishi servo motors, businesses can ensure that their automation systems remain agile and scalable, ready to meet future demands while harnessing their existing technological assets.

Mitsubishi servo motors are at the forefront of automation technology, significantly enhancing operational efficiency through advanced feedback mechanisms. These systems use high-resolution encoders that provide real-time feedback on motor position and speed, allowing for precise control even in complex applications. According to a recent report by Research and Markets, the global servo motors and drives market is expected to reach $13.12 billion by 2026, growing at a CAGR of 8.4%, driven by the demand for automation and precision in manufacturing processes.

The integration of advanced feedback technologies enables Mitsubishi servo motors to adapt in real-time to varying loads and operational conditions, significantly reducing the likelihood of errors. A study conducted by the International Journal of Advanced Manufacturing Technology found that systems employing advanced servo motor feedback mechanisms could improve accuracy by up to 30%, leading to enhanced product quality and reduced waste. This level of precision not only boosts production efficiency but also translates into cost savings, reinforcing the growing reliance on Mitsubishi servo motors in modern automation frameworks.