-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving landscape of automation, selecting the appropriate servo motor is crucial for enhancing efficiency and achieving desired performance in projects. According to a recent market research report by Mordor Intelligence, the global servo motor market is projected to reach $11.54 billion by 2026, driven by increasing demand for precision control in various applications, including robotics, CNC machinery, and assembly lines. This underscores the importance of understanding the specifications and applications of different servo motors, including variants such as the Siemens Servo Motor, which are highly regarded for their reliability and precision.

As industries continue to strive for automation and improved operational efficiency, the selection process must take into account various factors including torque requirements, speed, size, and feedback mechanisms. With the right servo motor, organizations can optimize their systems for improved performance and reduce downtime. Furthermore, industry experts highlight that the integration of advanced technologies such as IoT and AI into servo motor systems will further enhance functionality and facilitate smarter automation solutions. Thus, equipping oneself with knowledge on how to choose the right servo motor is imperative for engineers and project managers aiming to stay competitive in today’s automation landscape.

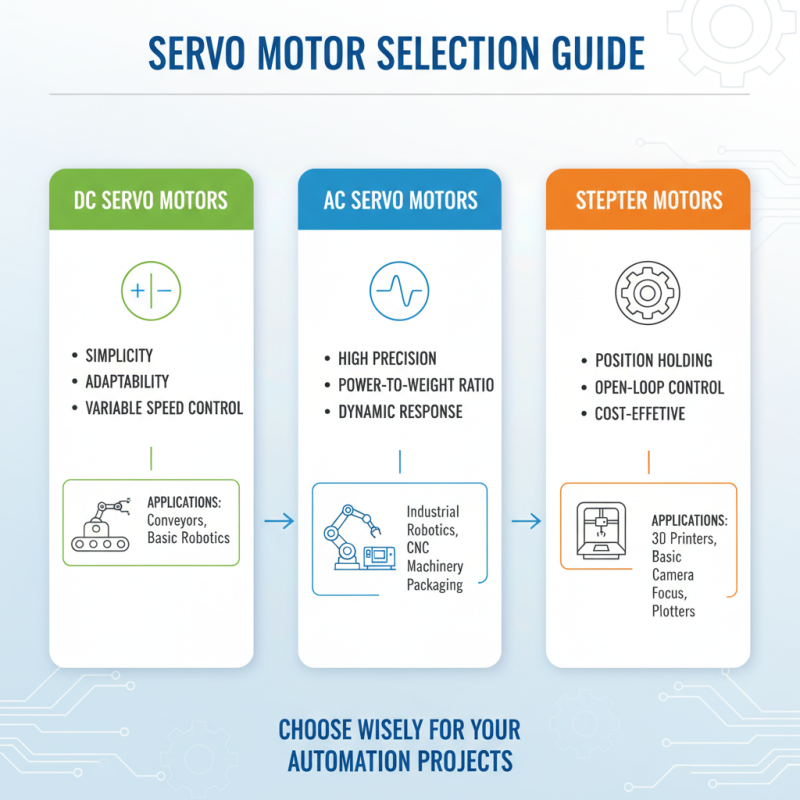

When selecting a servo motor for your automation projects, it's crucial to begin by understanding the different types available and how they align with your specific application needs. Servo motors can generally be categorized into DC, AC, and stepper motors. DC servo motors are known for their simplicity and adaptability, making them suitable for applications requiring variable speed control. On the other hand, AC servo motors typically offer higher precision and a greater power-to-weight ratio, which is essential in high-performance settings such as robotics and CNC machinery.

In addition to the basic types, consideration should also be given to specifications such as torque, speed, and feedback mechanisms. If your project involves precise movements or positioning, a servo motor with a high resolution encoder may be necessary. Conversely, for applications that prioritize continuous rotation or large torque, looking for motors with robust gear ratios could prove beneficial. Evaluating the operational environment—such as temperature range and potential exposure to dust or moisture—is equally important to ensure optimal performance and longevity of your chosen servo motor.

When selecting a servo motor for automation projects, it's crucial to comprehend the fundamental specifications: torque, speed, and voltage. Torque is a primary indicator of a servo motor's performance, defining its ability to overcome load resistance. According to a report by Technavio, the global servo motor market is expected to grow by over 20% between 2021 and 2025, primarily driven by the increasing demand for high torque motors. A servo motor capable of delivering adequate torque will ensure that machines operate smoothly under various loading conditions, thus enhancing efficiency and precision in automation tasks.

Speed is another critical specification that cannot be overlooked. Servo motors typically come with a rated speed that indicates how quickly they can respond to control signals. A study by MarketsandMarkets highlights that servo motors with quick speed response times are increasingly favored in industrial applications, particularly in robotics and CNC machines. For optimal performance, it's essential to match the motor's speed capabilities to the operational requirements of your project to avoid complications from overspeeding or insufficient acceleration.

Lastly, voltage ratings impact the motor's compatibility with existing systems and can influence performance characteristics such as efficiency and heat generation. The International Electrotechnical Commission notes that most servo motors operate on either low or high voltage inputs, with low voltage motors commonly preferred in compact applications. Understanding the relationship between voltage, current, and power consumption will enable engineers to select appropriate motors and design systems that maintain energy efficiency in the long run.

When selecting a servo motor for automation applications, it's essential to thoroughly evaluate the specific requirements of your project. One of the critical decisions is choosing between DC and AC servo motors. A recent report from the International Society of Automation indicates that around 60% of modern automation industries prefer AC servo motors due to their efficiency and ability to deliver higher power-to-weight ratios.

AC motors generally have better speed and torque characteristics over a range of operations, which translates to improved precision and reliability in applications like robotics and CNC machining.

However, DC servo motors still hold significant merit, especially in applications requiring simple control techniques and compact designs. According to a market analysis by Research and Markets, DC servo motors can achieve higher acceleration and deceleration rates when compared to their AC counterparts, making them ideal for applications that demand rapid movements.

Furthermore, the initial cost of DC systems tends to be lower, which is attractive for budget-constrained projects. Understanding these distinctions in efficiency and application suitability is vital for making an informed decision that will lead to optimal performance and longevity in your automation projects.

When selecting a servo motor for automation projects, understanding the differences between open-loop and closed-loop control methods is crucial. Open-loop systems operate without feedback, where the control signal is sent to the motor, but there is no mechanism to measure the actual position or velocity. This can be adequate for simple tasks where precise control is not critical. However, the lack of feedback can result in errors and inefficiencies, particularly as the load conditions vary. Reports from industry experts indicate that open-loop systems are generally less expensive and easier to implement, making them suitable for less demanding applications.

In contrast, closed-loop servo systems utilize feedback from sensors to monitor and adjust the motor's performance continuously. This results in higher precision, improved accuracy, and better performance under varying load conditions. A study by the International Federation of Robotics highlights that closed-loop systems can enhance efficiency by 20-30% in applications requiring high precision, particularly in fields like robotics and CNC machining. With this level of performance, it’s evident that while the initial investment may be higher, the long-term benefits in accuracy and maintenance costs can justify the choice of closed-loop control.

As automation technology continues to evolve, selecting the right control method plays a significant role in maximizing performance and achieving project goals.

When selecting the right servo motor for automation projects, assessing integration and compatibility with existing systems is crucial. First, it is essential to understand the operational environment where the servo motor will be deployed. Factors such as voltage requirements, communication protocols, and control methodologies must align with current automation technologies. For example, if your system utilizes a specific bus for communication, the servo motor must support the same protocol to ensure seamless integration without the need for complex adaptations.

Moreover, compatibility also extends to mechanical interfaces and physical dimensions. The servo motor’s mounting configuration should align with existing machinery to facilitate smooth installation. Incompatibilities in size or mounting can lead to modifications that unnecessarily complicate the project timeline and increase costs.

Additionally, evaluating the system’s power requirements and ensuring the selected motor can operate within the desired parameters is vital. This process not only guarantees smoother integration but also enhances overall efficiency in performance and reliability within the broader automation framework.