-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving industrial landscape, selecting the right Industrial Servo Motor for your application is crucial for optimizing performance and efficiency. According to a report by MarketsandMarkets, the global servo motor market is expected to grow from USD 6.6 billion in 2022 to USD 10.1 billion by 2027, reflecting a significant shift towards automation and precision in manufacturing processes.

With various types, torque ratings, and control mechanisms available, understanding the specific requirements of your application becomes essential. Factors such as load characteristics, motion profiles, and environmental conditions must be carefully considered to ensure the chosen Industrial Servo Motor delivers the desired operational outcomes.

As industries strive for greater efficiency and productivity, making informed decisions about servo motor selection can lead to substantial advantages in both cost and performance.

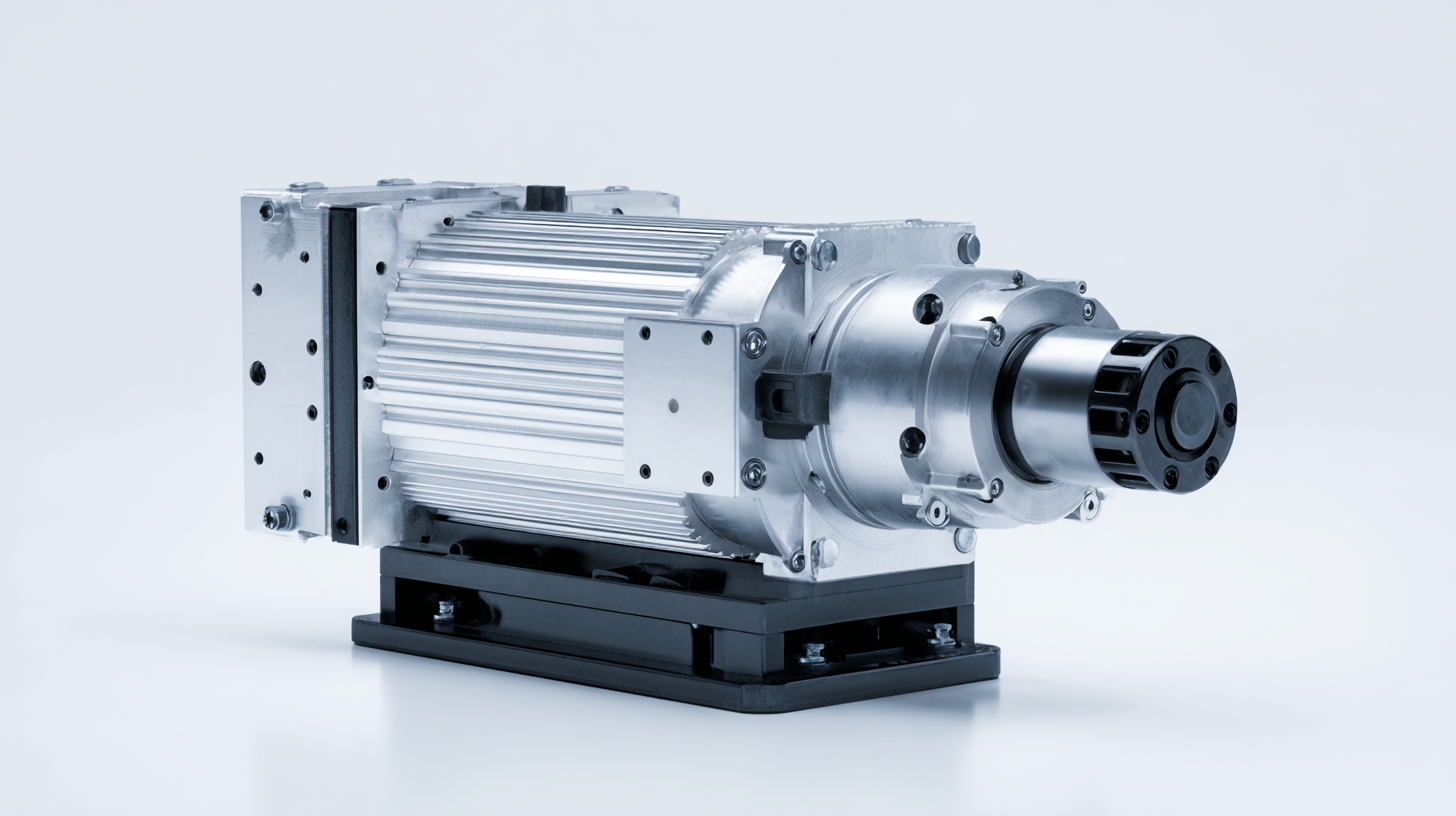

When selecting an industrial servo motor, an understanding of the different types available is crucial. Broadly, servo motors can be categorized into AC and DC types.

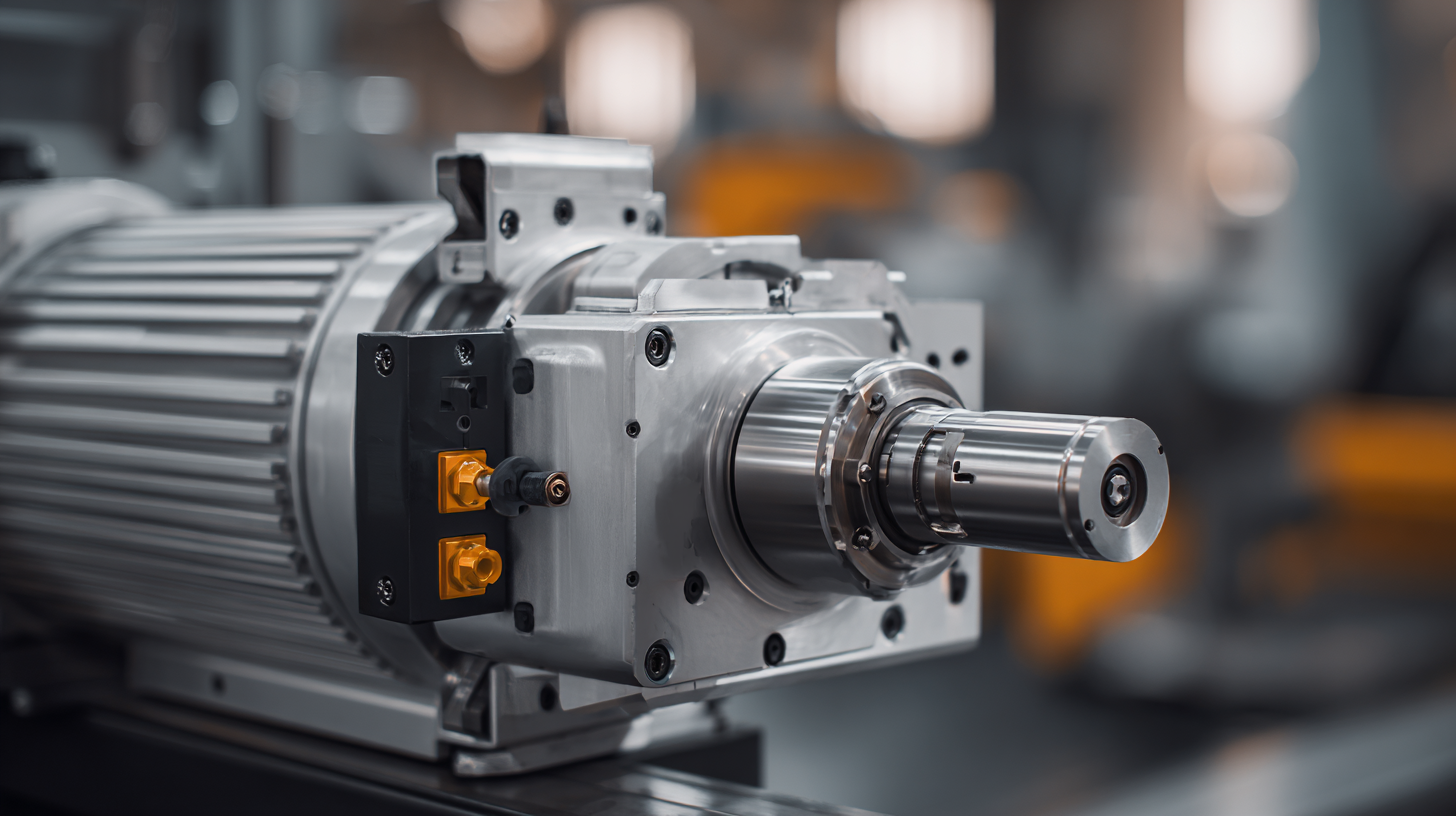

AC servo motors are known for their efficiency and are suitable for high-speed applications. They typically use a combination of alternating current and feedback systems to provide accurate positioning and speed control.

This makes them ideal for applications such as robotics and CNC machinery, where precision is paramount.

On the other hand, DC servo motors, which generally have simpler construction and control mechanisms, can be advantageous in applications that require high torque at low speeds. They offer straightforward speed control and are often used in smaller, less complex systems, like automation in packaging.

Additionally, stepper motors, a subset of DC motors, are popular in scenarios needing precise positioning without a feedback loop. Understanding these distinctions allows businesses to select the most suitable servo motor type that aligns with their operational requirements and application specifics.

When selecting an industrial servo motor, it's crucial to consider several key factors that can significantly influence the performance of your application. First, you need to assess the torque requirements of your system. This includes understanding the load characteristics and how quickly the motor needs to respond to changes. The torque rating should match or exceed the necessary performance level to ensure efficient operation and avoid potential system failures.

Additionally, the speed range of the servo motor is fundamental. Different applications require varying speeds, and selecting a motor that can operate within your specific speed parameters is essential for optimal functionality. Other factors to consider include the size and weight of the motor, as these can impact the installation and integration into your existing systems. It's also important to evaluate the motor's feedback mechanisms, such as encoders or resolvers, which provide critical information for precise control. By carefully analyzing these factors, you can make an informed decision that enhances your application's performance and reliability.

When selecting an industrial servo motor, understanding performance specifications is crucial to ensure that the motor will meet the requirements of your application. Key specifications to analyze include torque, speed, and position accuracy. Torque determines the motor's ability to handle load variations, while speed affects the overall responsiveness of the system. It is essential to choose a motor that not only delivers the required torque but also operates efficiently at the desired speed range for optimal performance.

In addition to torque and speed, one should pay attention to other parameters such as thermal limits, feedback mechanisms, and duty cycles. Thermal specifications inform users about the motor's capacity to dissipate heat, which is vital for prolonged use in demanding environments. Meanwhile, feedback systems, whether optical or magnetic, influence the precision of positioning in applications requiring high accuracy. Lastly, the duty cycle defines how long the motor can operate at full load and how it can handle intermittent tasks. By carefully analyzing these performance specifications, one can select a servo motor that not only fits the current needs but also contributes to the reliability and efficiency of the entire system.

When selecting an industrial servo motor, understanding the balance between cost and benefits is crucial. A recent report from Research and Markets highlights that the global servo motor market is projected to reach $9.0 billion by 2026, with a CAGR of 5.8%. This growth indicates that manufacturers are increasingly investing in advanced servo technologies that promise enhanced precision and efficiency in various applications. However, the initial price of these advanced options can be a significant consideration, especially for small to mid-sized enterprises.

Evaluating the long-term value of different servo motor options is essential. While low-cost motors may initially seem appealing, their performance can lead to higher maintenance costs and downtime, which ultimately affects productivity. For example, a study by the National Institute of Standards and Technology found that optimization of servo systems can reduce energy consumption by up to 30% and improve operational efficiency. Hence, investing in higher-quality servo motors may result in lower total cost of ownership when considering maintenance, efficiency, and productivity gains over time.

When selecting the right industrial servo motor for your application, it’s critical to assess its compatibility with existing systems and controls. Choosing a motor that integrates smoothly with your current infrastructure can save time, reduce costs, and enhance performance. Evaluate the specifications of the servo motor, such as voltage, current ratings, and communication protocols, ensuring they align with your existing equipment. This compatibility check will help in avoiding unnecessary modifications and disruptions during the integration process.

Furthermore, consider the control systems that manage the servo motors. A servo motor must be compatible with the controllers and software already in place. Assess the communication interfaces and ensure they can effectively transmit commands and feedback. This step is essential for maintaining the operational efficiency of the entire system. Making informed decisions based on compatibility can lead to a more robust and reliable automation solution that not only meets current needs but also adapts to future advancements in technology.

| Motor Type | Torque Rating (Nm) | Speed (RPM) | Voltage (V) | Control Method | Feedback Type |

|---|---|---|---|---|---|

| AC Servo Motor | 1.5 | 3000 | 230 | Voltage Control | Absolute Encoder |

| DC Servo Motor | 2.0 | 2000 | 24 | Current Control | Incremental Encoder |

| Stepper Motor | 0.8 | 1500 | 48 | Open Loop Control | None |

| Brushless Servo Motor | 3.5 | 4000 | 400 | Vector Control | Sin/Cos Encoder |