-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

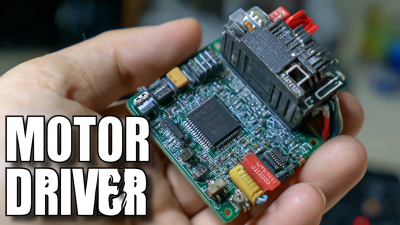

In the rapidly evolving world of electronics, the demand for efficient motor driver solutions has become increasingly critical. As reported by industry analysts, the global motor driver market is projected to reach USD 9.1 billion by 2026, growing at a CAGR of 6.2% from 2021. This surge is driven by advancements in automation, robotics, and electric vehicles, all of which require sophisticated motor driver systems to optimize performance and energy efficiency. As engineers and developers seek to enhance these solutions, several essential approaches can be leveraged to improve motor driver designs. This blog will explore practical examples of innovative techniques and strategies that not only elevate the performance of motor drivers but also ensure they meet the demands of various applications across multiple industries.

Motor driver design plays a critical role in the efficiency and performance of various applications, ranging from automated manufacturing to robotics. One of the most significant challenges faced by engineers is optimizing switching efficiency. According to a report by the International Electrotechnical Commission, more than 50% of the energy losses in motor systems can be attributed to inefficient motor driver designs. This inefficiency not only raises operational costs but can also lead to premature equipment failure, which is particularly concerning in industrial settings where uptime is crucial.

Another common challenge is thermal management. As reported by SPI Research, inadequate heat dissipation in motor drivers can reduce overall system reliability, resulting in up to a 20% decrease in system lifespan. Engineers must invest in robust thermal management strategies, including the use of heat sinks and advanced materials, to ensure long-term operation without overheating. By addressing these challenges head-on, designers can significantly improve their motor driver solutions, leading to higher efficiency and reliability in their applications.

When it comes to optimizing motor driver solutions, several key factors significantly influence their performance. One major element is the selection of appropriate driver architecture. Different applications may require differing levels of precision, speed, and efficiency. For instance, H-bridge configurations are ideal for bi-directional motion control, while half-bridges are often used for simpler, single-direction applications. Understanding the specific needs of your motor, such as load type and duty cycle, can guide you towards the right architecture, thus enhancing overall performance.

Another critical consideration is thermal management. Effective heat dissipation strategies can prevent overheating, which impacts driver reliability and lifespan. Components like heatsinks, thermal pads, and adequate ventilation can help maintain optimal operating temperatures. Additionally, the choice of driver components, including MOSFETs or IGBTs, should align with thermal capabilities to handle the current load without degradation. Balancing these factors ensures that the motor driver operates consistently under various conditions, ultimately leading to improved efficiency and prolonged service life.

When it comes to motor driver solutions, addressing common issues with innovative strategies is crucial for optimal performance. One prevalent problem is overheating, which can severely impact both efficiency and lifespan. Incorporating advanced heat dissipation techniques, such as adding heat sinks or utilizing thermal interface materials, can significantly mitigate this risk. Additionally, monitoring temperature through embedded sensors can provide real-time data, allowing for dynamic adjustments to the system to prevent overheating.

Another common challenge is noise in motor operation, which can affect the overall functionality and user experience. Implementing pulse-width modulation (PWM) for controlling motor speed can effectively reduce noise levels while maintaining precision. Moreover, using high-quality capacitors to filter out electrical noise can enhance the stability of the motor driver, ensuring smoother operation.

Lastly, achieving reliable communication between the motor and the driver is pivotal. Employing robust communication protocols such as CAN bus or RS-485 can enhance data transmission reliability. It’s also beneficial to include redundancy measures in your design to ensure that there are backup systems in place, minimizing the chances of failure during critical operations. By proactively addressing these issues, you can elevate the performance of your motor driver solutions significantly.

| Approach | Description | Benefits | Common Issues Addressed |

|---|---|---|---|

| Feedback Control Systems | Utilizing sensors to adjust motor performance in real-time based on load conditions. | Improved accuracy and responsiveness, leading to better performance. | Stability, torque issues, and overshoot. |

| Thermal Management | Implementing cooling solutions to manage heat generated by motor drivers effectively. | Extended component life and prevention of thermal shutdown. | Overheating, performance drops. |

| Advanced Gate Drivers | Utilizing high-speed gate driver ICs for improved switching performance. | Higher efficiency and reduced electromagnetic interference (EMI). | Switching losses, and EMI concerns. |

| Predictive Maintenance | Using data analytics to predict failures before they occur. | Reduced downtime and maintenance costs. | Unexpected failures, and operational interruptions. |

| Noise Reduction Techniques | Implementing dampening materials and optimized control algorithms. | Quieter operation and compliance with noise regulations. | Acoustic noise issues. |

When it comes to testing and validating motor drivers, adopting a robust methodology is essential for ensuring reliability and performance.

According to a report by MarketsandMarkets, the global motor driver market is projected to reach $2.82 billion by 2025, highlighting the

increasing demand for efficient motor control solutions. Effective testing practices must encompass not only the electrical parameters but also the thermal and mechanical conditions under which these drivers operate.

Utilizing automated testing rigs can simulate real-world scenarios, allowing engineers to spot potential failure modes before deployment.

Furthermore, industry standards such as the International Electrotechnical Commission (IEC) 61508 emphasize the importance of safety in motor driver applications, especially in

critical systems. Testing against these standards ensures compliance and enhances the trustworthiness of motor drivers. Additionally, implementing

Environmental Stress Screening (ESS) can reveal latent defects due to manufacturing inconsistencies, thus improving overall product quality.

This multidimensional approach not only validates performance but also fortifies the product development lifecycle, ultimately leading to greater market success.

The future of motor driver technology is set to revolutionize various industries, with key trends aimed at improving efficiency and performance. One significant development is the rise of smart motor drivers that leverage artificial intelligence for optimized control and predictive maintenance. This technology not only enhances system reliability but also reduces operational costs by anticipating failures before they occur.

Tip: Consider integrating AI-based algorithms in your motor driver solutions to maximize efficiency. These algorithms can analyze data in real time, adjusting performance parameters and ensuring optimal operation under varying conditions.

Another trend is the shift towards miniaturization and integration of motor drivers. As devices become smaller, the demand for compact and efficient motor drivers grows. This not only saves space but also improves energy efficiency. The incorporation of power electronics alongside advanced cooling techniques will be crucial for managing thermal challenges in these compact designs.

Tip: When designing for miniaturization, focus on selecting high-performance components that can handle increased power densities while maintaining thermal stability. This will ensure that your motor driver solutions remain reliable and efficient in small form factors.