-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the ever-evolving landscape of automation, Servo Motors have emerged as a crucial component driving efficiency and productivity. According to a recent report by MarketsandMarkets, the global servo motors market is projected to reach USD 9.96 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is largely attributed to the enhanced performance and precision that Servo Motors deliver in various applications, from robotics to manufacturing processes. By providing up to 30% more efficiency compared to traditional motors, these advanced actuators not only reduce energy consumption but also optimize operational time and output quality. As industries continue to embrace automation and seek sustainable solutions, the role of Servo Motors becomes increasingly pivotal in achieving significant gains in operational efficiency and cost savings.

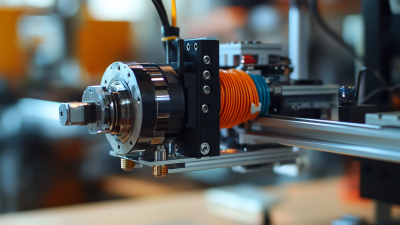

Servo motors have become a pivotal element in enhancing automation performance across various industries. These motors, known for their precision and control, significantly contribute to increased efficiency. According to a report by the International Energy Agency (IEA), implementing servo motors in industrial automation can boost system efficiency by up to 30%. This improvement is largely due to their ability to provide accurate positioning and speed control, reducing energy consumption during operations.

Additionally, a study by the Robotics Industries Association highlighted that servo motors offer a higher power-to-weight ratio compared to traditional motors, making them ideal for applications requiring high torque in compact spaces. This feature not only enhances the performance of automated systems but also leads to reduced wear and tear, ultimately extending the lifespan of machinery. As industries increasingly adopt automation solutions, integrating advanced servo motor technology is crucial for achieving optimal results and staying competitive in the market.

| Fact No. | Description | Efficiency Improvement (%) |

|---|---|---|

| 1 | Servo motors provide precise control of speed and position. | 30 |

| 2 | They reduce energy consumption by optimizing torque delivery. | 25 |

| 3 | Servo motors operate with low heat generation, extending service life. | 15 |

| 4 | They adapt quickly to changes in load conditions. | 20 |

| 5 | Servo motors enhance product quality with consistent operation. | 35 |

| 6 | They minimize mechanical wear thanks to their precise control. | 18 |

| 7 | Servo motors can be integrated with advanced control algorithms. | 28 |

| 8 | They support high-speed operations, increasing throughput. | 30 |

| 9 | Servo motors can handle higher load capacities than DC motors. | 22 |

| 10 | They enhance safety through precise and controlled movements. | 27 |

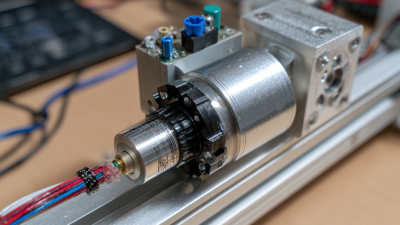

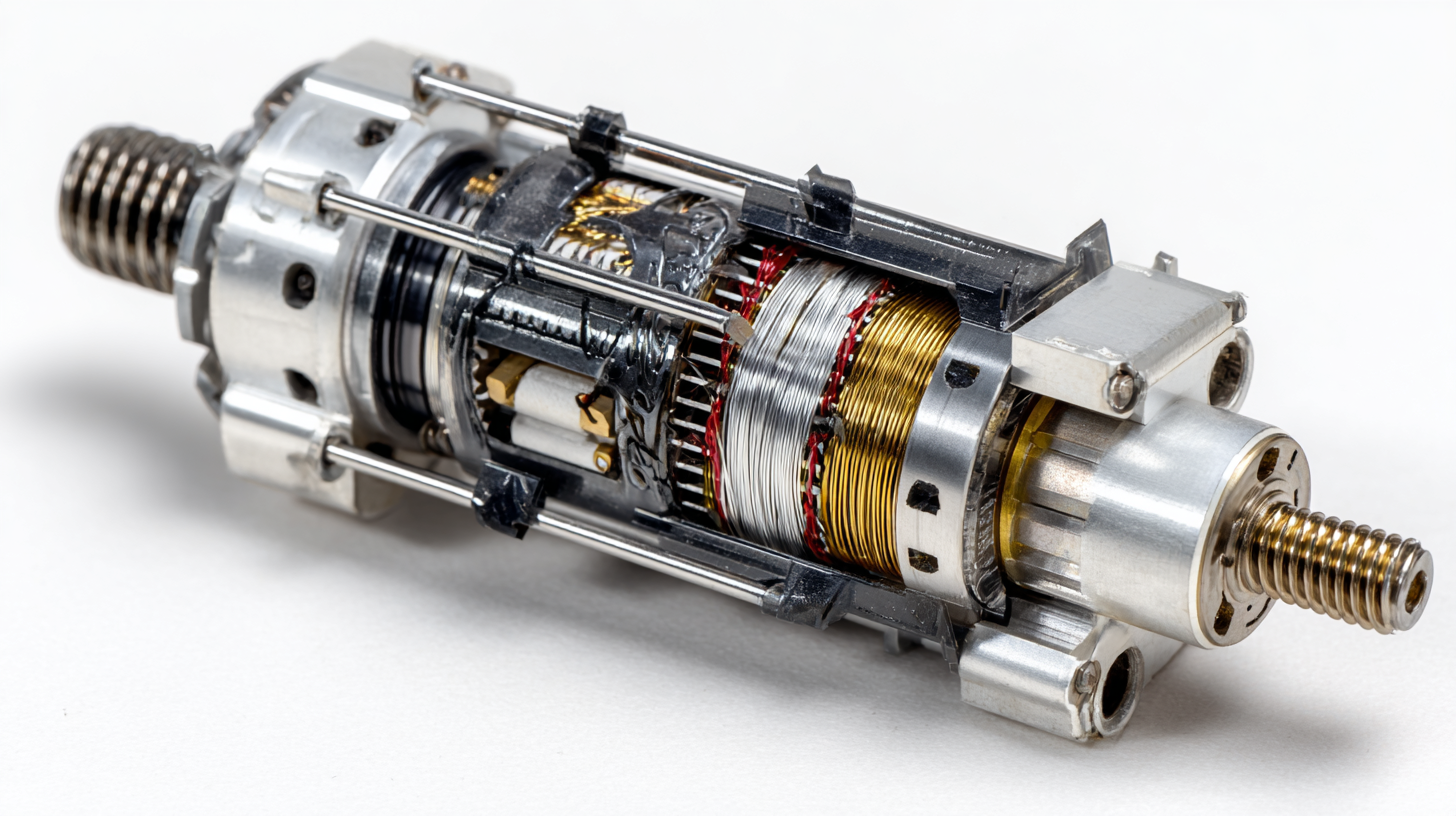

Servo motors are integral components in the realm of automation, particularly due to their remarkable efficiency. At the heart of their mechanics lies a closed-loop control system that allows for precise adjustments based on real-time feedback. This feedback mechanism ensures that the motor can continuously correct its position and speed, optimizing performance and energy usage. This level of control not only reduces wasted energy but also enhances the operational lifespan of the equipment, resulting in up to 30% more efficiency compared to traditional motors.

The design of servo motors also contributes significantly to their efficiency. Often featuring high-quality materials and advanced drive technologies, they can achieve superior torque and speed characteristics. This translates to reduced power consumption during operation, which is crucial for industrial applications requiring energy-intensive cycles. Additionally, servo motors can operate under varying loads without significant loss in performance, making them adaptable for diverse tasks and further promoting efficient energy use in automated systems. By understanding these mechanics, engineers can select and integrate servo motors effectively, driving efficiency in automated processes.

Servo motors play a crucial role in boosting operational efficiency within automation systems, contributing significantly to a 30% increase in overall productivity. One key factor driving this improvement is the precision control that servo motors provide. By enabling more accurate movements and positioning, they reduce cycle times and energy consumption, aligning perfectly with the growing demand for efficiency in various sectors, including manufacturing and logistics. According to a report, the pneumatic market is expected to grow from 21,187.28 million by 2025 to 35,592.47 million by 2033, which signifies a robust investment in automation technologies that enhance efficiency.

Servo motors play a crucial role in boosting operational efficiency within automation systems, contributing significantly to a 30% increase in overall productivity. One key factor driving this improvement is the precision control that servo motors provide. By enabling more accurate movements and positioning, they reduce cycle times and energy consumption, aligning perfectly with the growing demand for efficiency in various sectors, including manufacturing and logistics. According to a report, the pneumatic market is expected to grow from 21,187.28 million by 2025 to 35,592.47 million by 2033, which signifies a robust investment in automation technologies that enhance efficiency.

Moreover, automation technologies are not only pivotal in manufacturing but are also transforming industries such as cybersecurity. As modern enterprises face a shortage of skilled professionals in cybersecurity, automation can significantly elevate the overall security operations' effectiveness, addressing critical vulnerabilities. The infusion of intelligent automation solutions in processes marked by high speed and precision enhances both operational reliability and safety. As we move towards 2030, the integration of advanced automation techniques will continue to redefine efficiency standards across different sectors, showcasing the undeniable impact of technologies like servo motors in streamlining operations.

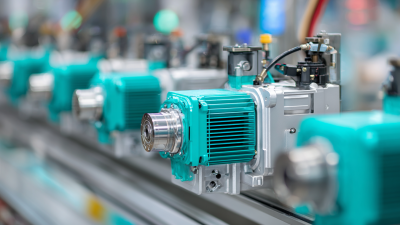

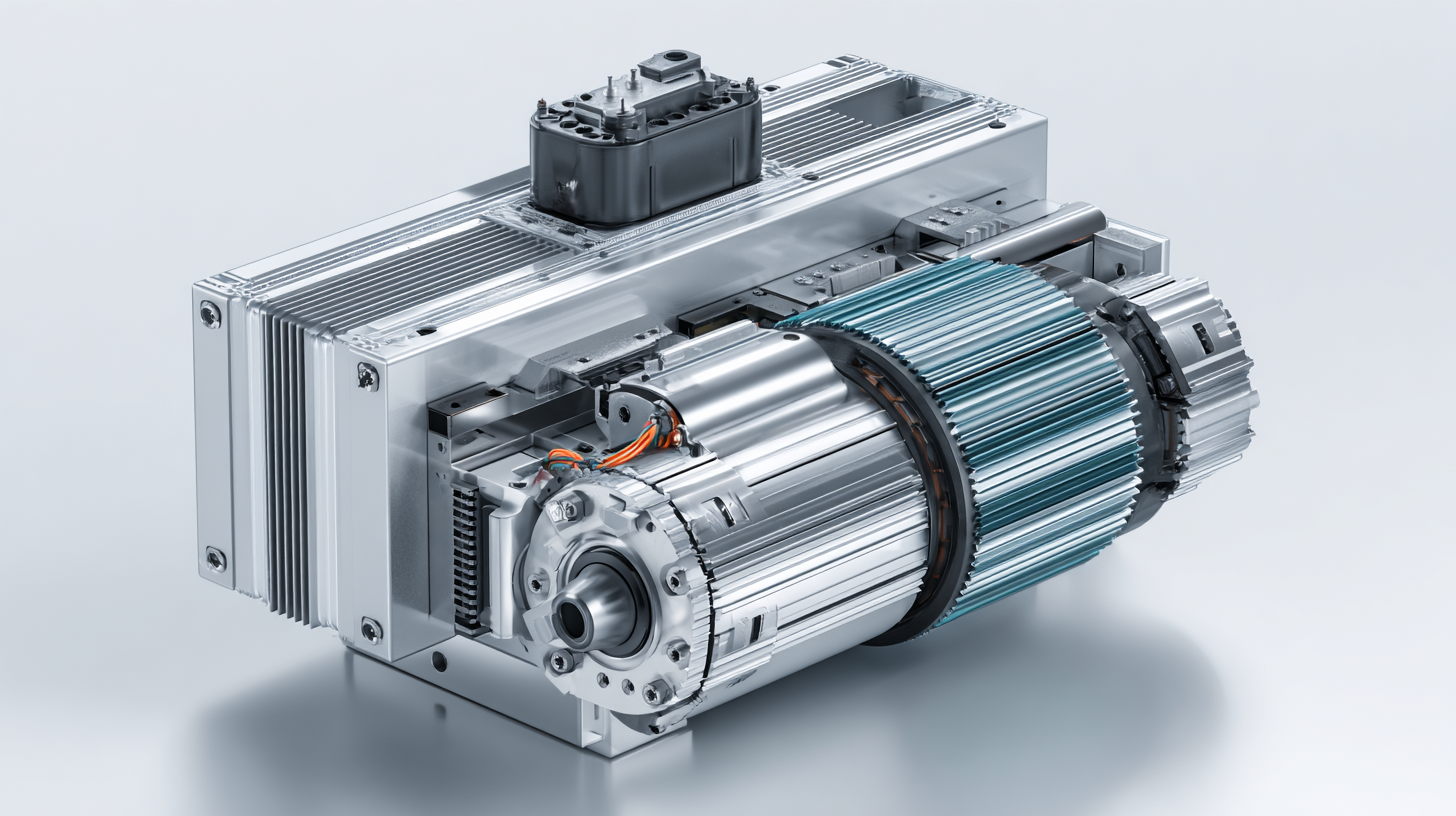

Servo motors are revolutionizing automation across various industries, providing significant advantages in precision, speed, and energy efficiency. According to a report by Allied Market Research, the global servo motor market is projected to reach $15.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.5%. This rapid growth is largely attributed to the increasing demand for high-performance automation systems in manufacturing, robotics, and aerospace applications.

One notable application of servo motors is in robotics, where they enable precise control of movement and positioning. These motors contribute to higher productivity rates and reduced operational costs. For example, an automotive assembly line that implements servo-driven robots can achieve up to 30% more efficiency compared to traditional methods. Additionally, in CNC machining, servo motors are essential for achieving the high accuracy required to create complex components; they ensure that the tools operate with reduced vibration and improved speed.

Tips: When integrating servo motors into your automation systems, consider investing in advanced control systems that can optimize their performance. Regular maintenance and calibration are vital to sustain efficiency over time. Moreover, it's beneficial to evaluate the specific torque and speed requirements for your application to select the right servo motor model, maximizing productivity while minimizing energy consumption.

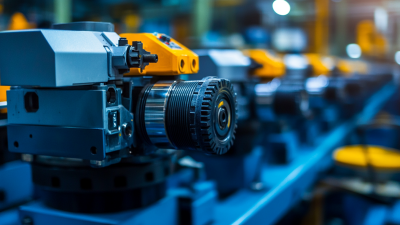

As industries increasingly prioritize efficiency and precision, servo motors are poised to play a pivotal role in shaping automation technology. These advanced motors, which offer unparalleled control and responsiveness, are at the forefront of innovations in robotics, manufacturing, and process automation. With the ability to deliver 30% more efficiency compared to traditional motors, servo technologies are revolutionizing how tasks are performed, leading to faster production times and reduced operational costs.

Future trends indicate that the integration of servo motors with cutting-edge technologies such as artificial intelligence and the Internet of Things (IoT) will further enhance their capabilities. By leveraging real-time data, servo motors can optimize performance, adapt to varying workloads, and improve maintenance management. These advancements not only promise to increase automation efficiency but also to foster smarter factories where connected systems can communicate seamlessly, driving productivity to new heights. The continued evolution of servo motors thus holds immense potential for transforming automation landscapes in the years to come.