-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

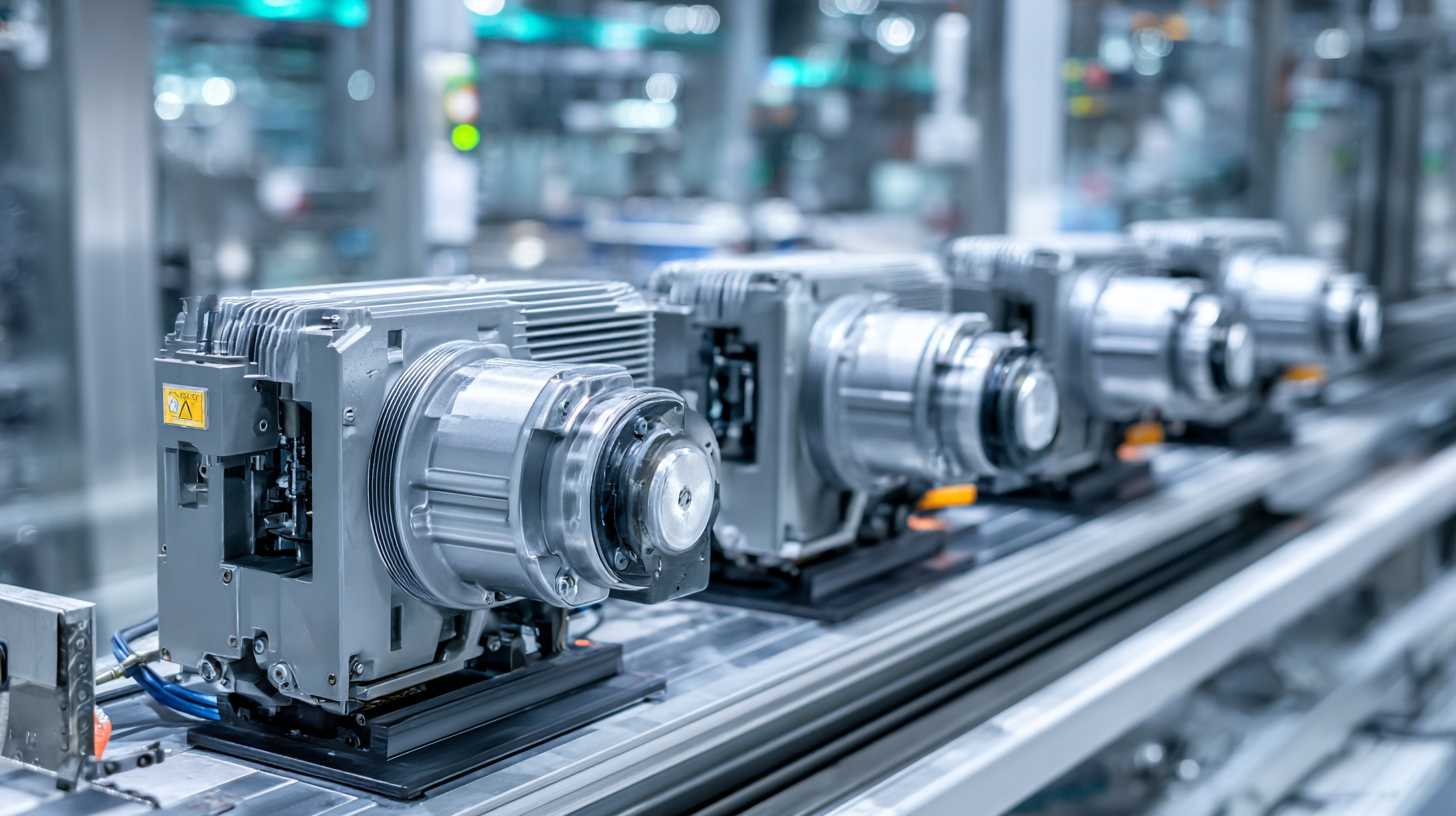

The increasing demand for precision and efficiency in automation applications has propelled the use of Industrial Servo Motors to the forefront of manufacturing innovations. According to a recent report by MarketsandMarkets, the global industrial servo motor market is projected to grow from USD 6.4 billion in 2020 to USD 9.5 billion by 2025, at a CAGR of 8.3%. This growth reflects the widespread adoption of servo motor technology in diverse sectors, including automotive, electronics, and food processing, where high-speed operation and accurate positioning are critical. Optimizing performance and efficiency with Industrial Servo Motors not only enhances productivity but also reduces operational costs, making them an indispensable component in modern industrial systems. As industries continue to evolve towards greater automation, understanding how to leverage these technologies effectively is vital for maintaining competitiveness and achieving long-term success.

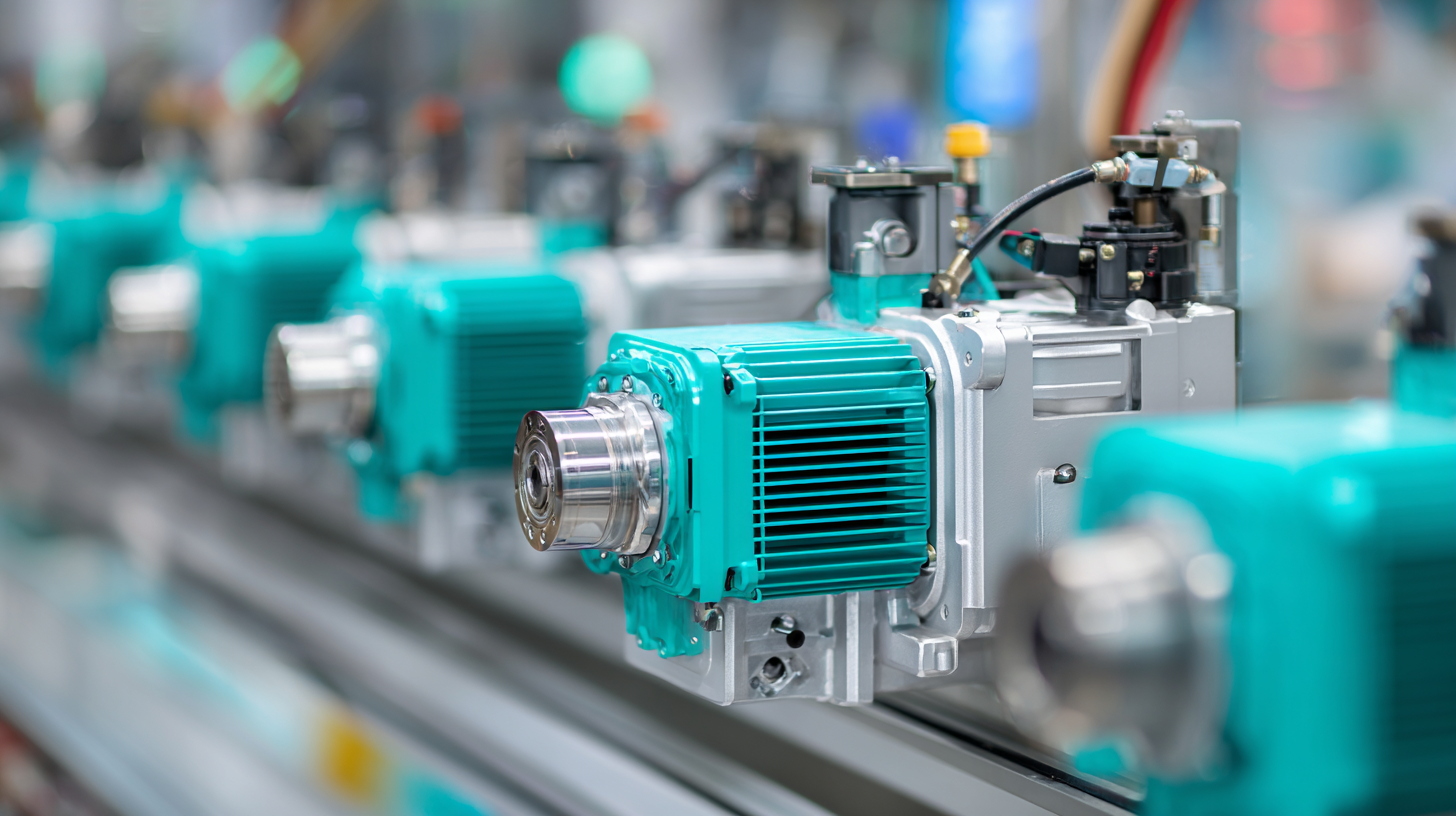

Industrial servo motors play a pivotal role in automation applications, assisting various industries, from manufacturing to robotics.

These motors are designed for precision control of angular and linear position, velocity, and acceleration, making them essential for applications that require high-speed and accurate movements.

According to a report by MarketsandMarkets, the global servo motor market is expected to grow from $7.26 billion in 2020 to $11.89 billion by 2025, representing a CAGR of 10.5%.

This growth is largely driven by the increasing demand for automation in various sectors, where servo motors optimize operational efficiency and enhance productivity.

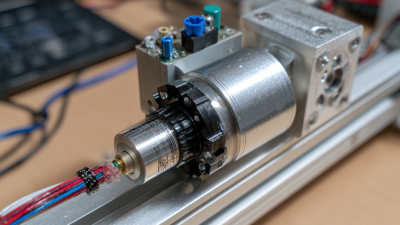

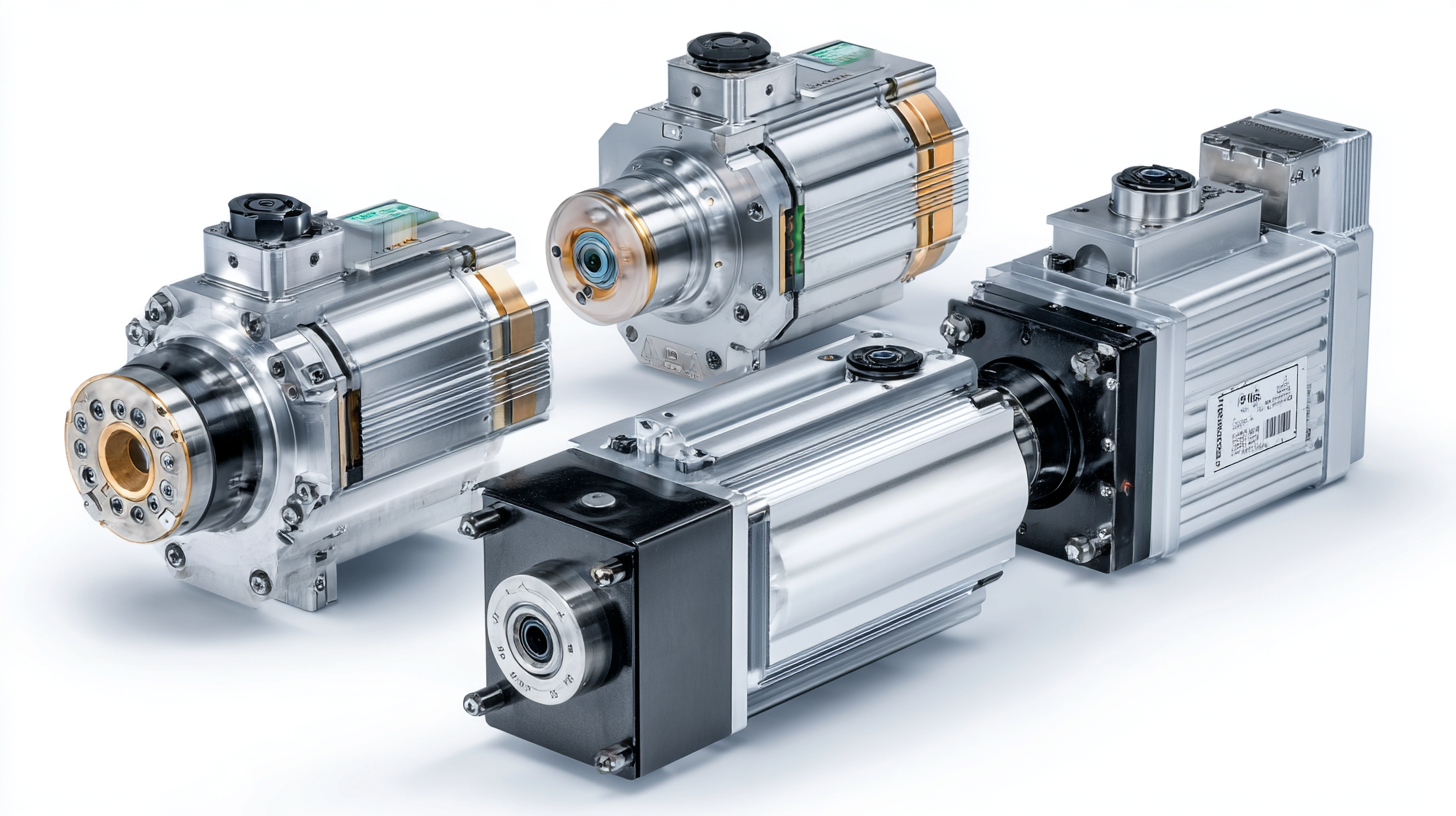

Understanding the basics of industrial servo motors involves recognizing their types - AC and DC servos - and their components, including encoders and gearheads.

AC servo motors are particularly favored for high-performance applications due to their robustness and efficiency in energy consumption.

A study from the International Energy Agency (IEA) highlights that implementing servo motors in automation can lead to energy savings of 30% to 50% compared to traditional motors.

As industries strive for performance optimization, the ability of servo motors to provide rapid feedback and adjustments allows for greater flexibility and higher throughput, making them an integral part of modern automated systems.

When it comes to automation applications, optimizing the performance and efficiency of industrial servo motors is crucial. The key performance metrics to assess servo motor efficiency include torque density, efficiency ratings, and thermal performance. According to a recent report by the International Energy Agency (IEA), electric motor systems, including servo motors, account for approximately 70% of industrial electricity consumption. This emphasizes the importance of choosing efficient motor solutions to reduce energy usage and operational costs.

To improve performance, consider monitoring the servo motor for its efficiency rating, which typically ranges from 75% to 95%. High-efficiency motors not only consume less energy but also deliver better torque density, allowing for maximal output from minimal input. Additionally, thermal performance is critical; maintaining optimal operating temperatures can enhance longevity and efficiency. Implementing a cooling system can further safeguard against overheating, which has been shown to cause efficiency degradation of up to 20%.

**Tips:** Regular maintenance and diagnostics play a vital role in sustaining optimal performance levels. Invest in a predictive maintenance strategy to foresee potential issues before they disrupt production. Moreover, recalibrating your servo motors in accordance with their operational environment can help maintain peak performance and mitigate efficiency losses.

This chart illustrates key performance metrics for evaluating the efficiency of industrial servo motors in automation applications. The data represents the efficiency (%) and torque (Nm) across different motor models.

Integrating servo motors into existing automation systems can significantly enhance both performance and efficiency. One key technique involves conducting a thorough analysis of the current system architecture. Understanding the specific requirements and limitations of existing equipment allows for the selection of servo motors that complement and enhance functionality. It is essential to consider factors such as torque, speed, and precision, ensuring that the servo motors align with the application's demands.

Moreover, adopting a modular approach during integration can streamline the process. This involves using standardized interfaces and communication protocols, which facilitate seamless interaction between the servo motors and other components of the automation system. Implementing advanced software solutions can also enhance integration efforts, allowing for real-time monitoring and control. These strategies not only optimize performance but also reduce downtime, making the transition to servo technology smoother and more efficient.

In the realm of automation, servo motors play a crucial role in enhancing performance and efficiency. Tuning these motors correctly can lead to significant improvements in operation. One essential practice is to regularly update the control parameters of your servo motors to match the specific demands of your applications. This ensures that the motors respond optimally to varying load conditions, leading to smoother operation and reduced stress on the system.

Tip: Always keep an eye on the feedback loops. Fine-tuning the gain settings can help achieve better stability and faster response times. Monitoring the system's performance metrics regularly allows for timely adjustments, thereby preventing potential issues before they escalate.

Maintenance also plays a pivotal role in preserving the functionality of servo motors. Routine inspections and cleaning can prevent dust and debris from affecting motor performance. Additionally, lubricating moving parts reduces friction, which can improve efficiency and prolong the lifespan of the servo motors.

Tip: Implement a preventive maintenance schedule that includes checking electrical connections and wiring integrity. This proactive approach can avert unexpected downtime and ensure your automation systems run seamlessly.

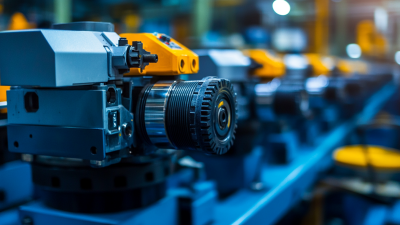

As industries increasingly lean towards automation, the evolution of servo motors stands at the forefront of enhancing operational efficiency. Future trends in servo motor technology focus on the integration of advanced communication protocols and artificial intelligence. These innovations enable seamless communication between machines, leading to more responsive and adaptive production processes. With the rise of Industry 4.0, the ability to collect and analyze data in real-time will drive servo motor design toward higher precision and lower energy consumption.

**Tips:** When selecting servo motors for automation applications, consider implementing models with built-in intelligence. This can streamline setup and maintenance and enhance adaptability to varying load conditions. Furthermore, investing in servo motors that feature regenerative capabilities can contribute to energy savings by allowing the system to recover energy during braking.

Another significant trend is the incorporation of IoT technologies, which enhances the monitoring and control of servo systems. Sensors embedded in servo motors allow for predictive maintenance, reducing downtime and extending the life of the machinery. Adopting these smart servo motors can lead to significant improvements in both productivity and efficiency.

**Tips:** Regularly update firmware and software associated with your servo motors to ensure you leverage the latest features, security updates, and performance enhancements. Also, consider environmental factors, such as ambient temperature and humidity, as they can significantly impact motor performance and lifespan.