-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

The advent of Direct Automation Plc has sparked a transformative wave across various industrial sectors, reshaping operational efficiencies and production capabilities. According to a report by McKinsey, automation technologies are projected to increase global productivity by up to 1.4% annually over the next decade, underscoring the significance of direct automation in enhancing efficiency. Furthermore, a study by the International Federation of Robotics highlighted that the demand for industrial robots, driven largely by direct automation innovations, has surged by 16% annually since 2018. This growth is indicative of a broader trend wherein manufacturers are increasingly adopting direct automation solutions to optimize processes and reduce labor costs. As industries grapple with rising operational demands and workforce challenges, Direct Automation Plc stands at the forefront of this automation revolution, offering cutting-edge technologies that promise to redefine the benchmarks of productivity and operational excellence in the modern industrial landscape.

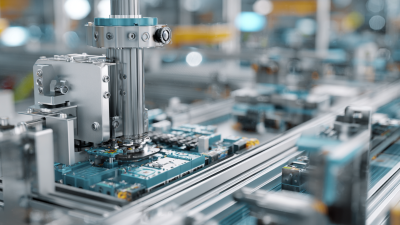

Direct Automation Plc has positioned itself at the forefront of the automation technology sector, significantly influencing modern industry. With advancements in AI and machine learning, the company has developed systems that not only enhance productivity but also improve accuracy in manufacturing processes. According to a report by the International Federation of Robotics, the global stock of operational industrial robots reached approximately 3 million units in 2022, illustrating a 12% year-over-year growth. This surge reflects a wider trend in automation adoption, with companies like Direct Automation Plc leading the charge by offering innovative solutions that integrate seamlessly with existing workflows.

Moreover, Direct Automation Plc's commitment to research and development has resulted in cutting-edge technologies that optimize supply chains and reduce operational costs. Their latest automation solutions, which incorporate IoT devices, facilitate real-time data analysis and predictive maintenance, effectively minimizing downtime. A study by McKinsey & Company indicates that organizations that deploy advanced automation technologies can achieve productivity boosts of 20-30%, underscoring the critical role that firms like Direct Automation Plc play in shaping the future of industrial operations. As industries increasingly embrace automation, the contributions of Direct Automation Plc are driving significant advancements that promise to redefine efficiency and productivity standards.

| Technology | Description | Impact on Industry | Adoption Rate (%) |

|---|---|---|---|

| Robotic Process Automation (RPA) | Use of software robots to automate routine tasks. | Increases efficiency and reduces operational costs. | 65 |

| Artificial Intelligence (AI) | Machine learning algorithms to analyze data and make decisions. | Enhances decision-making processes and predictive analytics. | 70 |

| Internet of Things (IoT) | Network of devices that collect and exchange data. | Improves monitoring and management of industrial processes. | 55 |

| Predictive Maintenance | Using analytics to predict equipment failures before they occur. | Reduces downtime and maintenance costs. | 60 |

| 3D Printing | Additive manufacturing technology to create objects layer by layer. | Enables rapid prototyping and customization. | 40 |

The manufacturing landscape is undergoing a significant transformation as companies increasingly adopt direct automation solutions to enhance their operations. With AI playing a pivotal role, the integration of smart technologies is enabling manufacturers to streamline processes, reduce emissions, and improve energy efficiency. This shift is particularly crucial as industries face growing pressures to innovate and keep pace with evolving market demands.

Innovative automation technologies are not only driving efficiency but also fostering sustainability, enabling businesses to align with global net-zero ambitions. As seen in various sectors, the implementation of AI-driven automation empowers manufacturers to navigate complexities, enhance productivity, and remain competitive in an ever-changing industrial environment. By embracing these advancements, companies are set to create a transformative impact on modern industry, paving the way for a smarter and more sustainable future.

The integration of automation, particularly through the efforts of companies like Direct Automation Plc, has become a cornerstone for enhancing efficiency and productivity across various industries. As businesses strive to unlock value and reassess their operational processes, the strategic advantages of automation are becoming increasingly evident. This shift not only streamlines workflows but significantly reduces operational costs and enhances the overall quality of products and services. By implementing intelligent automation solutions, companies can elevate their performance while maintaining agility in a competitive marketplace.

Moreover, the rise of AI in industrial settings is revolutionizing decision-making processes and driving innovation. With generative AI technologies paving the way for optimized value chains, organizations are experiencing heightened scalability and security in their operations. As industries embrace the tenets of Industry 4.0, characterized by technological integration and data-driven insights, they are positioned to achieve sustainable growth and resilience. Through continuous adaptation and investment in automation, businesses can cultivate a culture of efficiency that not only meets current demands but also anticipates future challenges in an ever-evolving landscape.

This chart showcases the percentage improvement in efficiency across various industries as a result of implementing automation technologies. The data reflects significant gains, particularly in healthcare and finance, highlighting the transformative potential of automation in modern industry.

Direct Automation Plc has been at the forefront of transforming modern industry through its innovative automation solutions. A notable case study is its partnership with a leading automotive manufacturer, which implemented Direct Automation's robotic assembly lines. This integration led to a 30% reduction in production time and a 25% decrease in operational costs, as evidenced by a recent report from the International Federation of Robotics. Such improvements not only enhance efficiency but also improve product quality, significantly impacting the industry's competitive landscape.

Another compelling success story comes from a food processing enterprise that adopted Direct Automation's advanced monitoring systems. By leveraging real-time data analytics, the company achieved a 40% increase in throughput and reduced waste by 15%. According to the Food and Beverage Industry Technology Conference, automation in this sector is projected to drive annual cost savings of over $100 billion by 2025. This highlights how Direct Automation's initiatives do not just streamline processes but also contribute positively to sustainability efforts within modern enterprises, reshaping the economic viability of their operations.

The integration of Direct Automation Plc in the landscape of Industry 4.0 marks a significant evolution in the manufacturing sector. As industries pivot towards smart manufacturing, the projected growth of this market from $394.35 billion in 2025 to $998.99 billion by 2032 embodies the substantial economic shift we are witnessing. Central to this transformation is the reliance on advanced technologies, with automation systems becoming indispensable in enhancing operational efficiency and productivity.

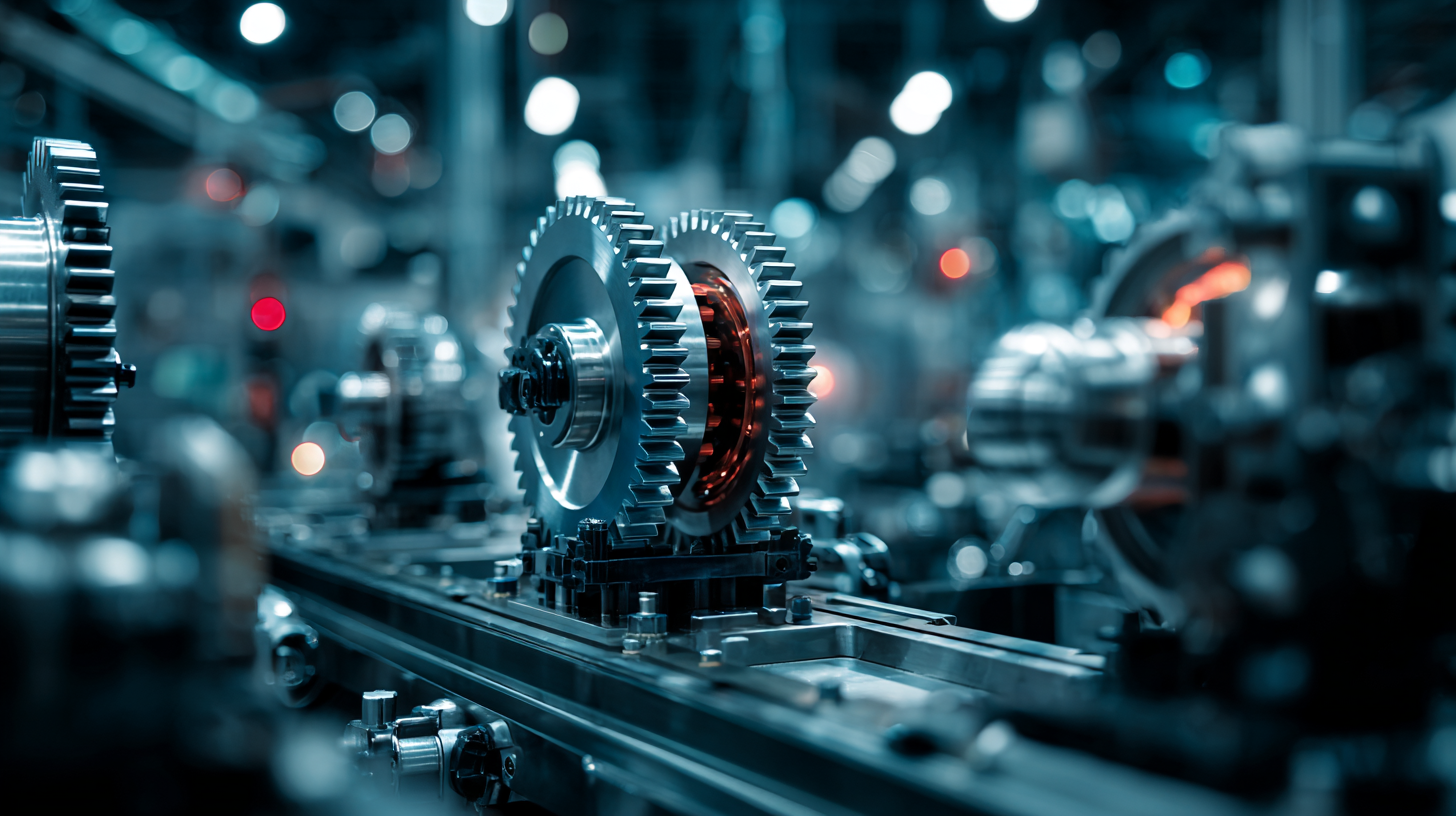

Motors serve as the fundamental components that propel machinery within automated environments. Their efficiency and reliability are crucial in streamlining manufacturing processes, enabling industries to achieve higher levels of output while reducing waste. Additionally, the surge in the IO-Link market, expected to reach a valuation of USD 13.5 billion by 2032, emphasizes the growing importance of connectivity and real-time communication in industrial automation. The effective interplay of these technologies will drive industries towards a more integrated and intelligent manufacturing future, laying the foundation for innovative practices and robust economic growth.