-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

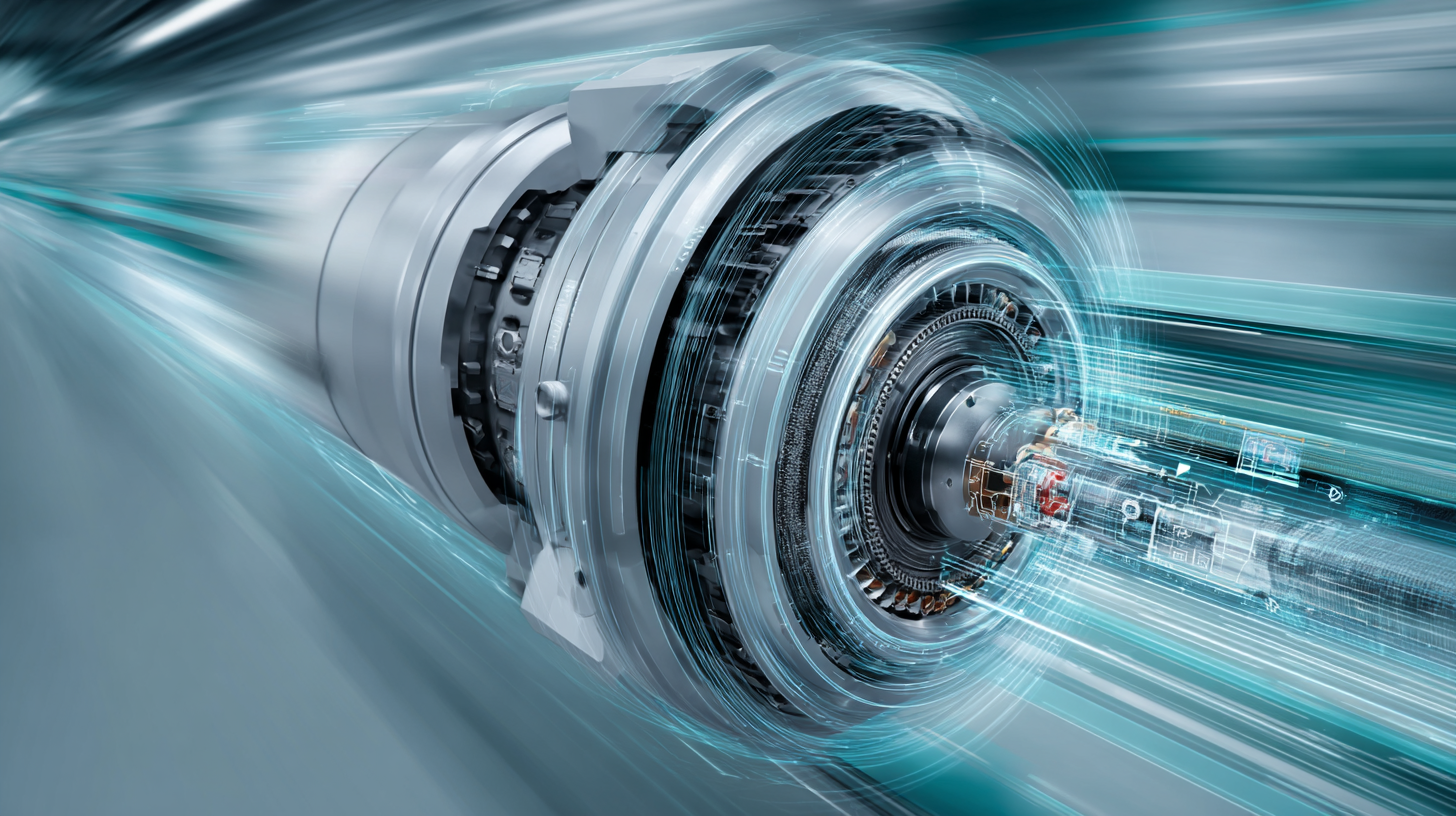

In the rapidly evolving landscape of automation systems, efficiency and precision are paramount. The introduction of Siemens Servo Motors stands at the forefront of this technological transformation, providing unparalleled performance that is reshaping various industries. By harnessing advanced engineering and innovative design, Siemens Servo Motors enable modern automation systems to perform with remarkable accuracy and responsiveness, significantly enhancing overall productivity.

The integration of Siemens Servo Motors not only optimizes operational workflows but also offers solutions for complex motion control applications. These motors are engineered to meet the demands of today's automated environments, where speed, reliability, and adaptability are crucial. As industries increasingly lean towards fully automated processes, the role of Siemens Servo Motors becomes even more critical, paving the way for smarter and more efficient production lines.

As we delve into the impact and functionality of Siemens Servo Motors in modern automation systems, it is essential to explore their unique features and benefits. This examination will reveal how these advanced motors contribute to unlocking efficiency, driving innovation, and ultimately leading to a new era of industrial automation that is smarter, faster, and more efficient than ever before.

Siemens servo motors have emerged as a pivotal component in modern automation systems, presenting significant advantages in energy efficiency and cost reduction. By integrating advanced technology, these servo motors optimize performance while consuming less energy compared to traditional motors. This efficiency not only leads to lower operational costs but also supports sustainability initiatives, making them an ideal choice for businesses aiming to reduce their environmental footprint.

Tips: When selecting a servo motor, consider the specific application requirements such as torque, speed, and load characteristics. This ensures that the chosen motor operates within its optimal range, maximizing both energy savings and performance. Regular maintenance and monitoring of motor performance can also help identify inefficiencies early, allowing for timely interventions that enhance longevity and efficiency.

Furthermore, the precision control offered by Siemens servo motors enables companies to streamline their production processes. By improving the accuracy of movements and minimizing waste, businesses can achieve higher productivity levels with reduced material and energy costs. Adopting these motors not only lowers expenses but also enhances product quality, leading to long-term savings and customer satisfaction.

| Dimension | Value |

|---|---|

| Energy Efficiency Improvement (%) | 20-30% |

| Reduction in Operational Costs ($) | 5000-10000 |

| Return on Investment (ROI) Period (Years) | 1-3 |

| Reduction in Maintenance Costs (%) | 10-15% |

| Increase in Productivity (%) | 15-25% |

| Lifespan Increase (Years) | 5-10 |

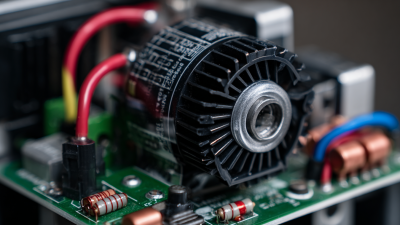

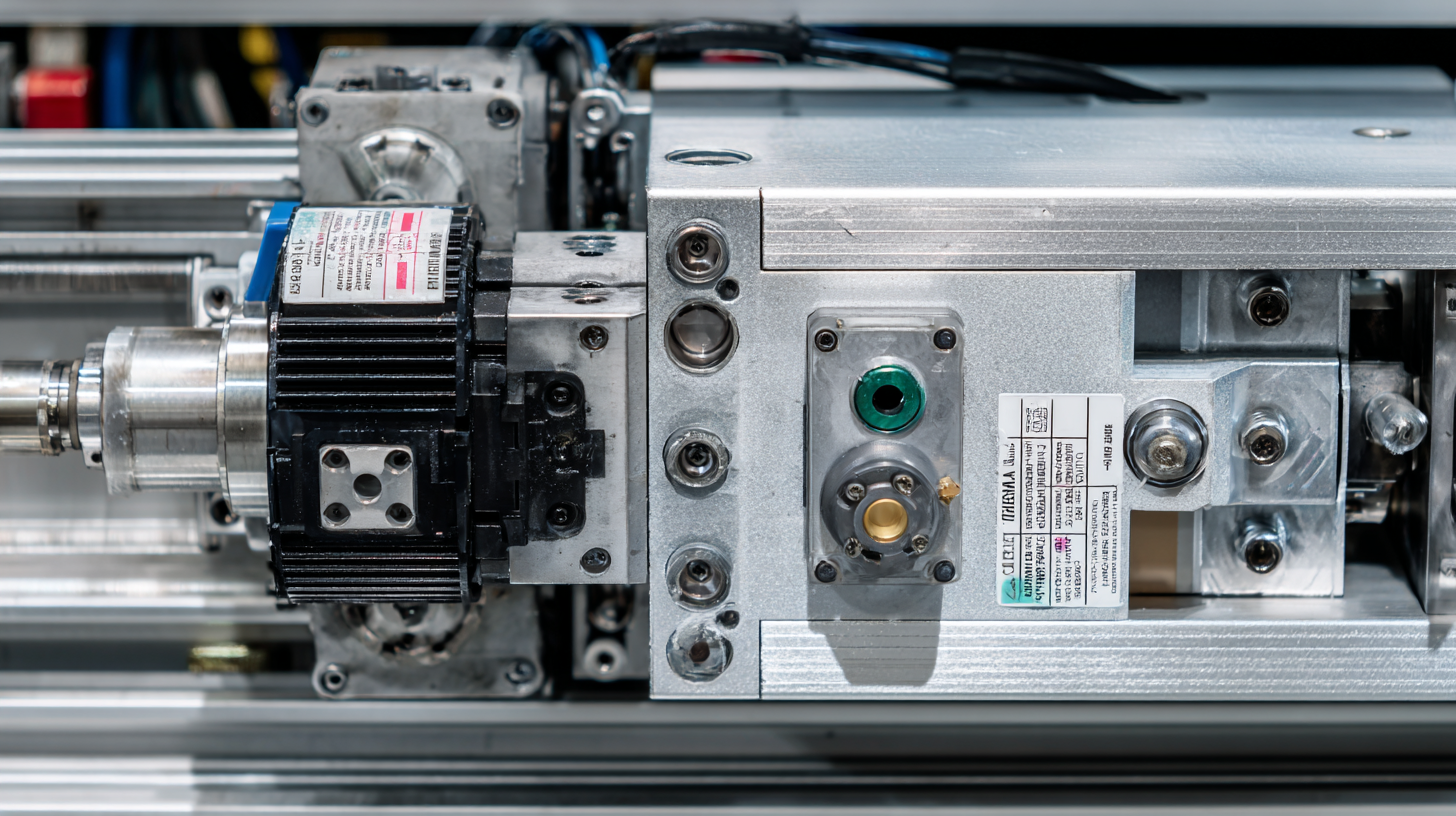

Siemens servo motors have emerged as pivotal components in modern automation systems, characterized by their precision, speed, and efficiency. One of the key features enhancing their performance is the advanced feedback control. This technology allows for real-time monitoring of motor position and speed, ensuring that systems operate with exceptional accuracy. The incorporation of high-resolution encoders plays a critical role, enabling seamless communication between the motor and the control system, thus facilitating precise adjustments during operation.

Siemens servo motors have emerged as pivotal components in modern automation systems, characterized by their precision, speed, and efficiency. One of the key features enhancing their performance is the advanced feedback control. This technology allows for real-time monitoring of motor position and speed, ensuring that systems operate with exceptional accuracy. The incorporation of high-resolution encoders plays a critical role, enabling seamless communication between the motor and the control system, thus facilitating precise adjustments during operation.

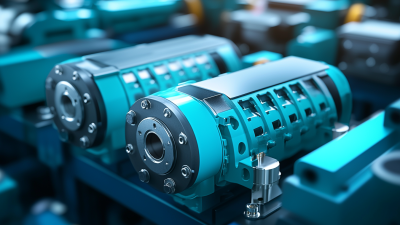

Another significant feature of Siemens servo motors is their compact design, which optimizes space in increasingly miniaturized automation environments. This not only simplifies system integration but also enhances reliability through reduced mechanical wear and tear. Additionally, Siemens motors offer robust thermal management capabilities, ensuring consistent performance even under high load conditions. This combination of features makes Siemens servo motors an ideal choice for industries looking to improve productivity and reduce downtime, ultimately unlocking the full potential of modern automation systems.

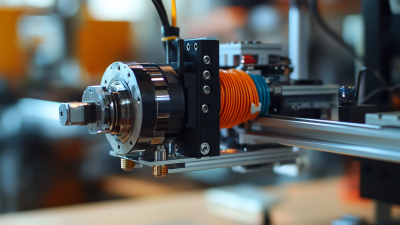

The integration of servo motors into modern industrial applications is transforming automation systems across various sectors. The global integrated servo motor market is anticipated to grow significantly, driven by increasing demand for precision and efficiency in manufacturing processes. According to industry reports, the market is projected to reach over $20 billion by 2025, with a compound annual growth rate (CAGR) of approximately 8%. The rise in automation within industries such as automotive, electronics, and food and beverage is propelling this growth, highlighting the essential role of high-performance servo motors.

In particular, advanced servo drive systems are setting the bar for dynamic applications, offering unmatched acceleration and response times. The introduction of innovative technologies enhances not only operational efficiency but also the ability to handle complex movements with utmost precision. This shift towards higher standards in performance is evident, as industries are increasingly adopting AC and DC servo motors tailored for low, medium, and high-voltage applications. By leveraging these cutting-edge solutions, businesses can significantly improve productivity and reduce downtime, solidifying their competitive edge in an ever-evolving market landscape.

Siemens servo motors have increasingly gained traction in modern automation systems, offering distinct advantages over traditional actuators. According to a recent report by Mordor Intelligence, the global servo motors market is projected to reach $8.11 billion by 2025, signifying a shift in demand towards high-performance solutions. When comparing Siemens servo motors to traditional actuators, a key differentiator lies in their precision and energy efficiency. Siemens servo systems can reduce energy consumption by up to 30% compared to conventional actuators, enhancing overall operational efficiency.

Tips: When considering automation upgrades, it's crucial to evaluate energy costs and performance capabilities. Investing in Siemens servo motors can lead to substantial savings and improved productivity in the long run. As companies prioritize sustainability, adopting these advanced systems not only supports operational goals but also aligns with environmental initiatives.

Moreover, Siemens servo motors provide better feedback and control, allowing for faster response times in dynamic applications. A study conducted by Research and Markets reports that businesses utilizing servo technology experienced a 25% increase in production speed. This improved performance translates directly into reduced cycle times and higher output, making a compelling case for the transition from traditional actuators to advanced servo solutions.

Siemens servo motors are at the forefront of enabling Industry 4.0, representing a significant transformation in automation systems. With the increasing integration of the Internet of Things (IoT) and smart manufacturing, these motors offer enhanced precision, efficiency, and adaptability in production processes. According to the 2022 International Federation of Robotics report, the global demand for industrial robots is projected to reach $70 billion by 2025, a clear indication of the shift towards automated solutions. Siemens servo motors play a crucial role in this evolution, providing the necessary torque and responsiveness needed in modern manufacturing lines.

As industries move towards greater connectivity and real-time data utilization, Siemens servo motors are becoming indispensable. A study by MarketsandMarkets indicates that the servo motor market is expected to grow from $9.41 billion in 2020 to $15.91 billion by 2025, driven by the trend of increasing automation in manufacturing. The adaptability of Siemens servo solutions allows companies to implement flexible automation systems that can easily accommodate changes in production volumes and product specifications. This aligns perfectly with the principles of Industry 4.0, promoting efficiency and reduced downtime, and ultimately leading to significant cost savings and higher productivity.