-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

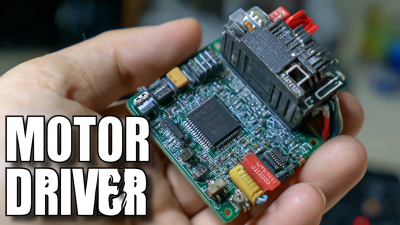

In the realm of motion control systems, the significance of motor drivers cannot be overstated. These critical components serve as the interface between the control signals and the motors, enabling precise and efficient operation. Understanding motor drivers is essential for engineers and designers who strive for optimal motor control solutions, as the performance of the entire system hinges on the capabilities and characteristics of the driver chosen. This article delves into the top five reasons why a comprehensive understanding of motor drivers is pivotal in achieving unparalleled control and efficiency in various applications.

Motor drivers not only facilitate the conversion of incoming signals to the appropriate outputs for motors, but they also directly impact the overall responsiveness, accuracy, and reliability of the system. In scenarios ranging from robotics to industrial automation, the choice of motor driver can influence energy consumption, heat generation, and the longevity of the motor itself. By examining the intricacies of motor drivers, professionals can make informed decisions that enhance system performance, minimize downtime, and optimize energy efficiency. Ultimately, this deeper understanding empowers engineers to tailor solutions that meet the unique demands of their projects, paving the way for innovation in motor control technologies.

In the realm of industrial automation systems, motor drivers play a pivotal role in enhancing operational efficiency and productivity. According to a report by MarketsandMarkets, the global motor driver market is projected to grow from $2.0 billion in 2020 to $3.3 billion by 2025, reflecting an annual growth rate of 10.7%. This surge underlines the increasing reliance on advanced motor control solutions to optimize performance across various applications, including robotics, conveyor systems, and manufacturing equipment.

Motor drivers are essential for ensuring that motors operate at their optimal performance levels, which directly influences the efficiency of industrial processes. For instance, a study by the International Energy Agency (IEA) reveals that electric motors account for about 45% of global electricity consumption in industrial applications. By employing sophisticated motor drivers that feature precise control algorithms, manufacturers can achieve significant energy savings—up to 30% in some cases—while reducing wear and tear on mechanical components.

This not only enhances the longevity of equipment but also leads to lower operational costs, showcasing the critical importance of understanding and implementing the right motor driver technology in modern industrial automation systems.

Understanding motor drivers is crucial for achieving energy efficiency and sustainability in manufacturing. As industries strive for cleaner and smarter operations, advanced motor control solutions become essential. Efficient motors and drives help significantly reduce energy consumption, directly impacting operational costs and environmental footprints. By optimizing motor performance, manufacturers can transition toward more sustainable practices, ensuring their processes are aligned with modern energy standards and regulations.

The integration of innovative motor technologies can transform key manufacturing sectors in various regions. For instance, certain initiatives emphasize the role of electrification and automation in promoting sustainable industrial growth. By focusing on energy-efficient motor designs and applications, manufacturers not only lower their energy consumption but also enhance overall productivity. The shift towards sustainable machine design further amplifies these benefits, allowing companies to minimize waste and reduce their environmental impact while maintaining cost-effectiveness in their operations.

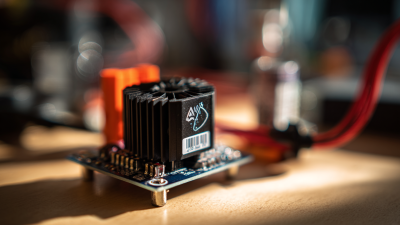

The landscape of motor driver technology is rapidly evolving, and understanding the latest trends and innovations is crucial for developing optimal motor control solutions by 2025. One of the key trends is the integration of artificial intelligence (AI) in motor drivers, providing enhanced performance through predictive maintenance and adaptive control. AI algorithms can analyze performance data in real-time, allowing for adjustments that improve efficiency and reduce energy consumption, making systems smarter and more responsive.

Another significant innovation is the miniaturization of motor drivers, which contributes to the growing demand for compact and efficient designs in various applications, from automotive to industrial machinery. This trend is accompanied by advancements in materials technology, such as the use of silicon carbide (SiC) and gallium nitride (GaN), which enable higher power densities and improved thermal management in smaller packages. As these technologies mature, they open up possibilities for more powerful and efficient drive systems while facilitating the transition to electric and hybrid vehicles, ultimately shaping the future of motor control solutions.

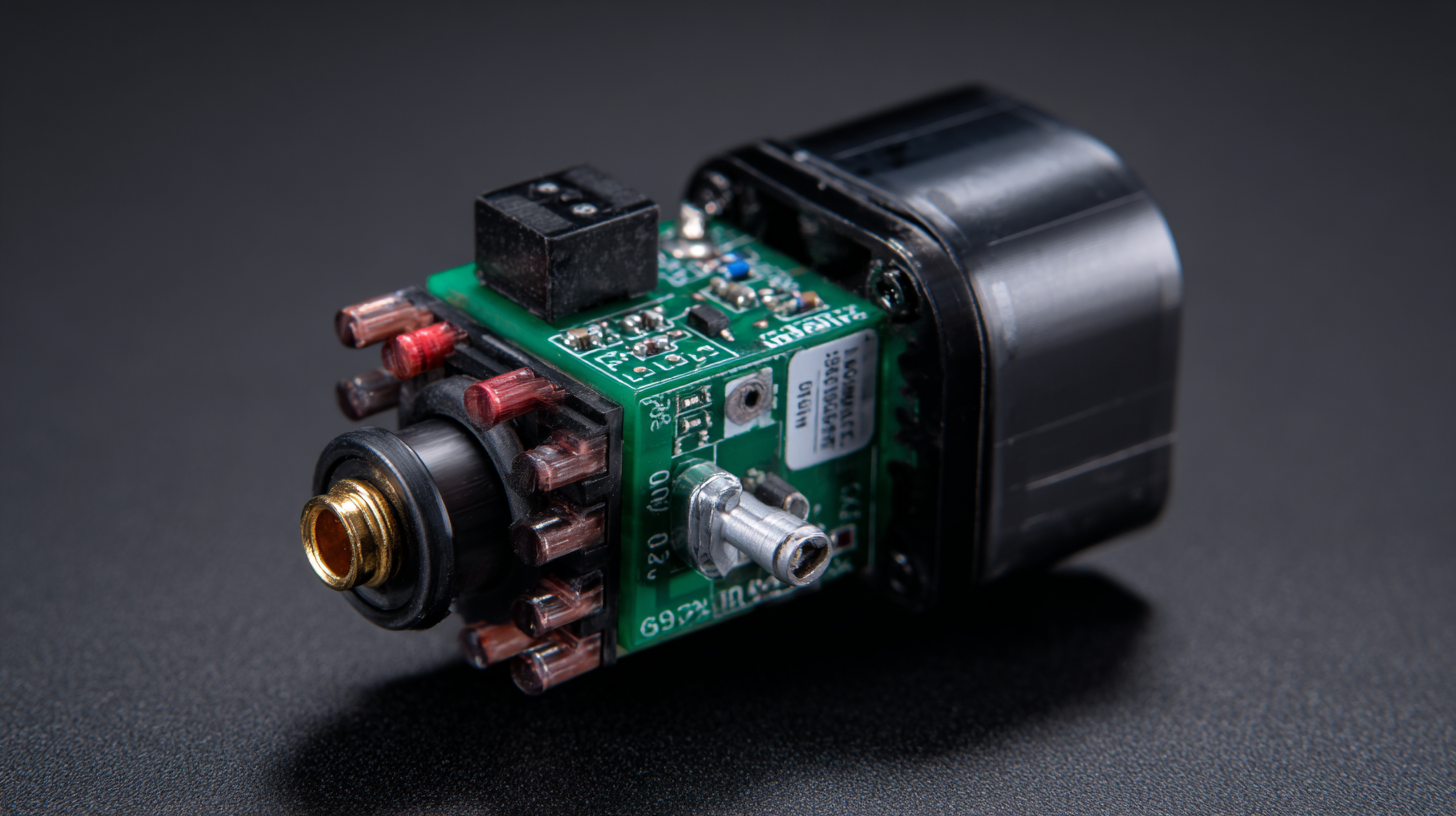

In the realm of automation, the distinction between motor drivers and controllers is pivotal for achieving optimal motor control solutions. Motor drivers serve as the interface that translates control signals into mechanical movement by powering the motor, while controllers are responsible for managing the overall operations based on desired performance parameters. A comparative analysis reveals that selecting the right driver can enhance efficiency and responsiveness.

According to a report by MarketsandMarkets, the electric motors market is expected to reach $178.4 billion by 2026, highlighting the importance of effective motor control solutions in industrial applications.

Drivers, such as stepper motor drivers, provide precise control and are crucial in applications requiring accuracy, like 3D printing and CNC machines. A study published in the IEEE Transactions on Industrial Electronics indicates that the right motor driver can improve torque efficiency by 15-20%, leading to significant energy savings and extended equipment life. In contrast, controllers capable of intelligent data processing contribute to predictive maintenance and performance optimization, ensuring that the system operates within its optimal parameters.

As industries continue to evolve towards automation, understanding these components individually and how they interact will be essential for maximizing performance and minimizing operational costs.

Understanding motor drivers is pivotal for achieving optimal motor control solutions, particularly when examining real-world implementations. Case studies reveal that organizations leveraging advanced motor driver technologies have significantly improved their operational efficiency. For example, in sectors like transportation, companies utilizing AI-driven software report reductions in fuel consumption and delays through real-time optimizations. This approach mirrors trends observed in manufacturing, where integrating smart technologies leads to enhanced production efficiency and cost savings.

**Tips:**

1. **Prioritize Predictive Maintenance:** Organizations should implement predictive maintenance strategies to foresee motor failures, which can extend equipment lifespan and reduce downtime.

2. **Embrace Data-Driven Insights:** Utilize data analytics from motor driver performances to inform operational decisions, ensuring continuous improvement in efficiency.

3. **Invest in Training:** Equip your team with knowledge on the latest motor driver technologies and control solutions to drive innovation and maintain a competitive edge.

Real-life examples highlight the impact of effective motor driver solutions. Industries are witnessing transformations through strategic implementations that not only boost productivity but also foster remarkable customer experiences. With over 1,000 documented success stories of technological integration, it is evident that understanding motor drivers is not just beneficial, but essential for driving organizational success in diverse fields.

| Case Study | Industry | Motor Type | Driver Technology | Performance Improvement |

|---|---|---|---|---|

| Automated Packaging System | Manufacturing | Stepper Motor | Digital PWM Driver | 30% increase in efficiency |

| Robotic Arm Precision | Robotics | DC Servo Motor | Closed-loop Driver | 20% better accuracy |

| Electric Bicycle Control | Transportation | Brushless DC Motor | Field-Oriented Control Driver | 15% longer battery life |

| CNC Machining Efficiency | Machinery | AC Induction Motor | Variable Frequency Drive (VFD) | 25% reduction in cycle time |

| Conveyor System Optimization | Logistics | Synchronous Motor | Smart AC Drive | 40% reduced energy consumption |